Electric Vehicle Battery Compression Pad & Cushioning Solutions

Battery compression pads and cushioning solutions from JBC Technologies help the batteries of today’s electric and hybrid electric vehicles perform reliably and safely under even the most demanding conditions.

We manufacture custom compression and cushioning components capable of withstanding the relentless stresses of fluctuating battery cell compression and operating temperature.

Have an EV battery compression pad or cushioning challenge?

EV Battery Compression Pads & Other Cushioning Applications

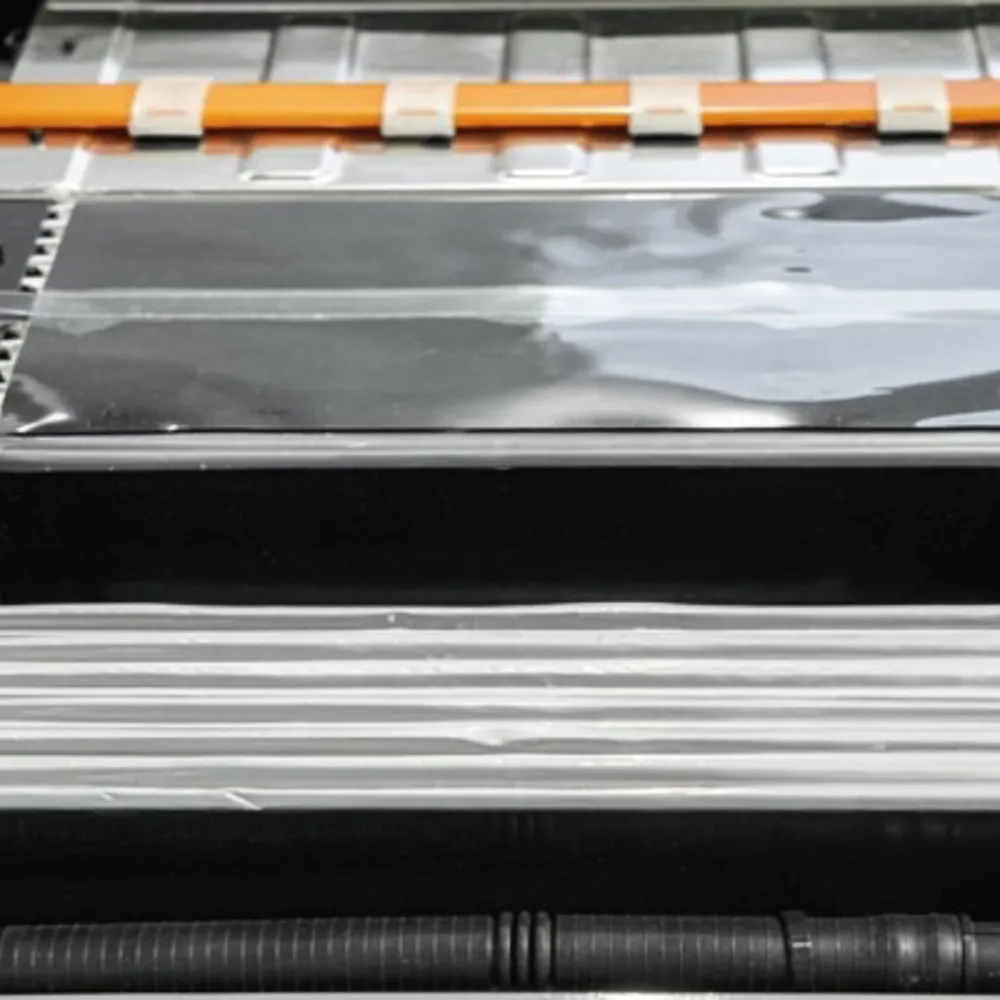

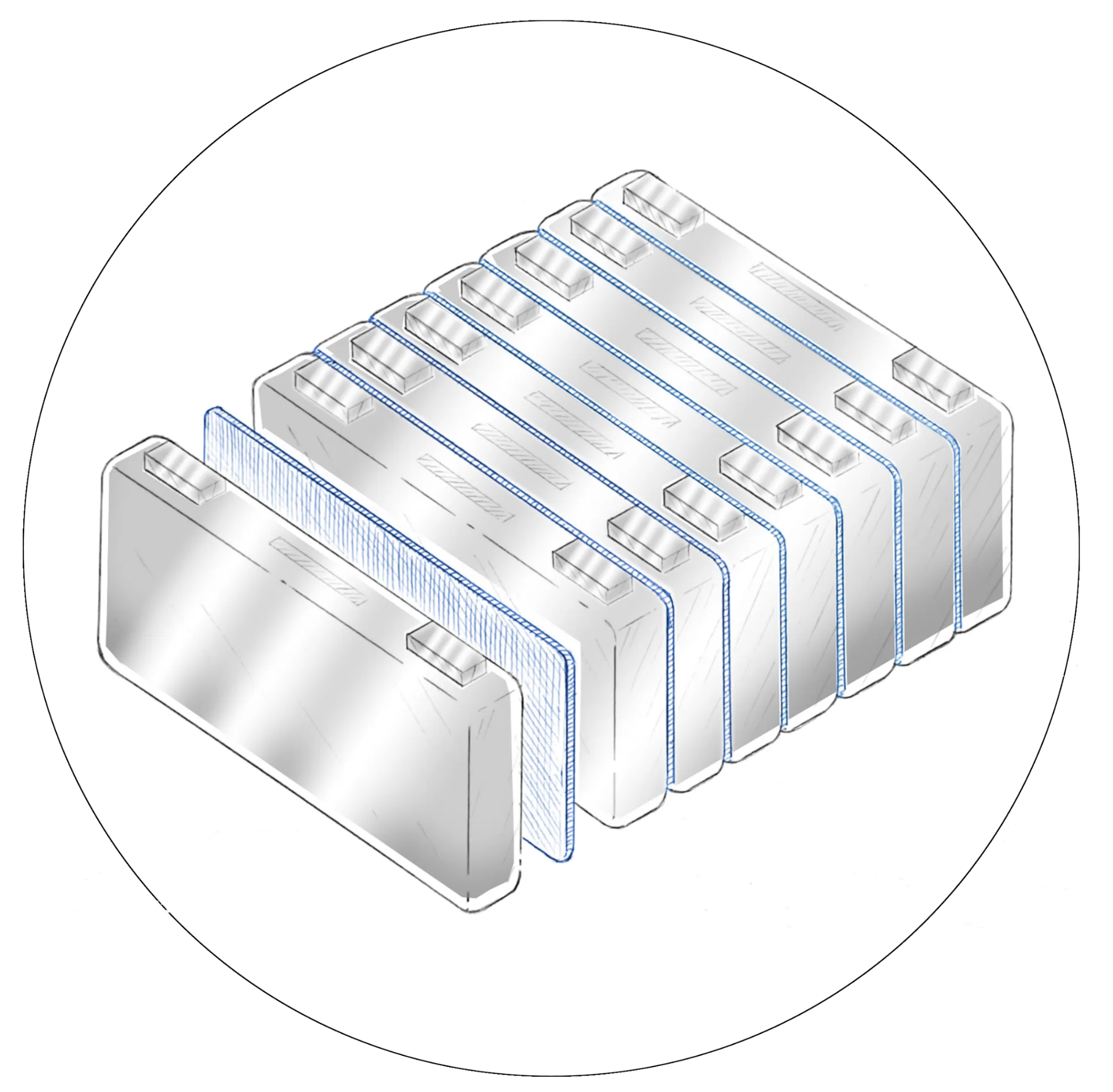

EV battery compression and cushioning solutions from JBC are designed for pouch and prismatic style batteries and target both cell-to-cell and cell-to-end applications.

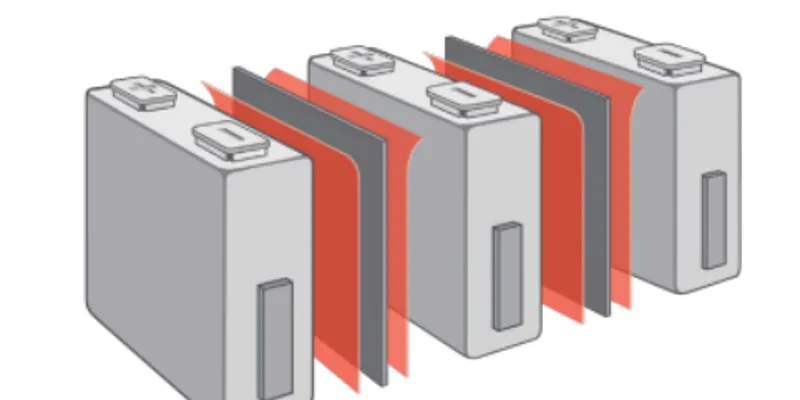

Compression cushions lessen vibration and stress damage to the battery's internal components, which is crucial for any delicate automotive electronic system. Additionally, cushioning makes for a quieter EV ride and helps distribute vibration by removing and isolating potential road noise.

Several areas for custom die-cut components that target vibration and compression include

- Battery Cell Compression

- Battery Module Cushioning

- Cooling Plate Spring Pads

- Pack Vibration Damping

---

battery cushions and compression pads used within an electrical vehicle’s battery pack must be firm enough to hold components in place and compressible enough to withstand recurrent dimensional changes over the battery’s lifetime.

pERFORMANCE MATERIALS for ev battery compression & cushioning

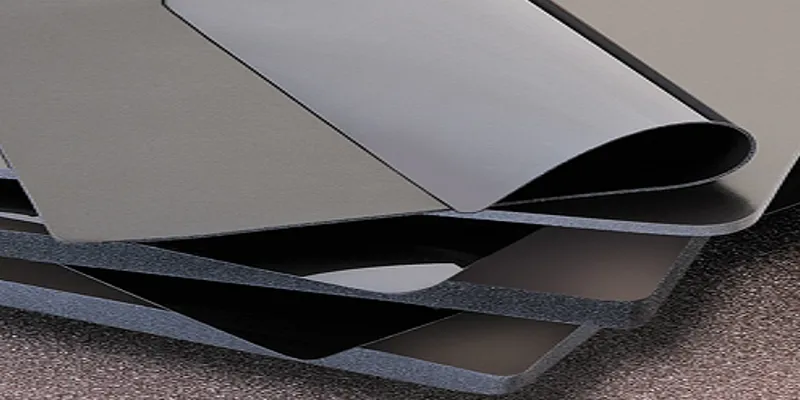

A precision die-cut part is only as good as the material from which it’s made. JBC can combine different performance materials into multi-layer laminate compression/cushioning solutions with performance that’s greater than the sum of its parts.

Our in-house material and application experts have decades of experience and we’re proud to be a 3M Preferred Converter, Berry Elite Converter, and Avery Dennison ADvantage converter partner.

We have strong relationships with the industry’s leading material manufacturers, and are here to help us find the materials that will work best for your EV battery compression and cushioning application.

Here are a few of the specialty materials available for your custom EV battery die-cut cushions and compression pads

Hi Temperature Rated Adhesive Tapes

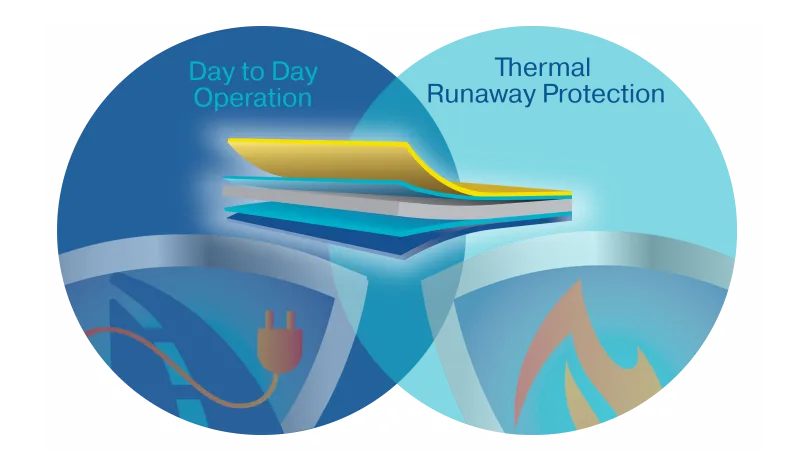

EV batteries require special adhesive tapes for their compression applications. Adhesive tapes must often be tested against UL (Underwriters Laboratories) 94 for flammability performance or UL-Listed for safety regulations. Adhesive tapes can be used to encapsulate dusty or flaky compression pads or as assembly aids during pack assembly.

Ceramic Fiber Compression Papers

EST compression papers from Morgan Thermal Ceramics are designed to accommodate the cyclical expansion of pouch and prismatic battery cells experience during normal operation. Designed to go between either pouch or prismatic battery cells to delay flame propagation in case of thermal runaway.

Microcellular Polyurethanes

Microcellular polyurethane foams like Rogers PORON EVExtend® make great anti-vibration pads and are proven in automotive applications, supplying solutions like vibration damping and noise isolation. These materials withstand the collapse caused by the stresses of compression and temperature over time, extending the battery's life by continuing to seal and absorb shock.

Specialty Automotive Foams

Die cut gaskets for noise, vibration, and harshness (NVH) and buzz, squeak, squeak, and rattle (BSR) support quieter vehicle interiors, stronger feelings of quality, and increased customer satisfaction. Die cut NVH gaskets reduce or eliminate unwanted sounds and the unpleasantness often caused by road noise.

Partner with a Premier Converter For Custom Die-Cut Compression Pad and Cushioning Solutions

When you choose to work with JBC Technologies for your custom cell-to-cell, cell-to-end, compression pads and pack and module level cushioning solutions, you’re not only getting a world-class converter and precision die cutting expert, but you’re also getting the backing and experience of some of the leading material manufacturers in the industry.

Whether you’re looking for single-material, adhesive backed solution or a multi-material, custom laminated stack-up, you can count on JBC Technologies.