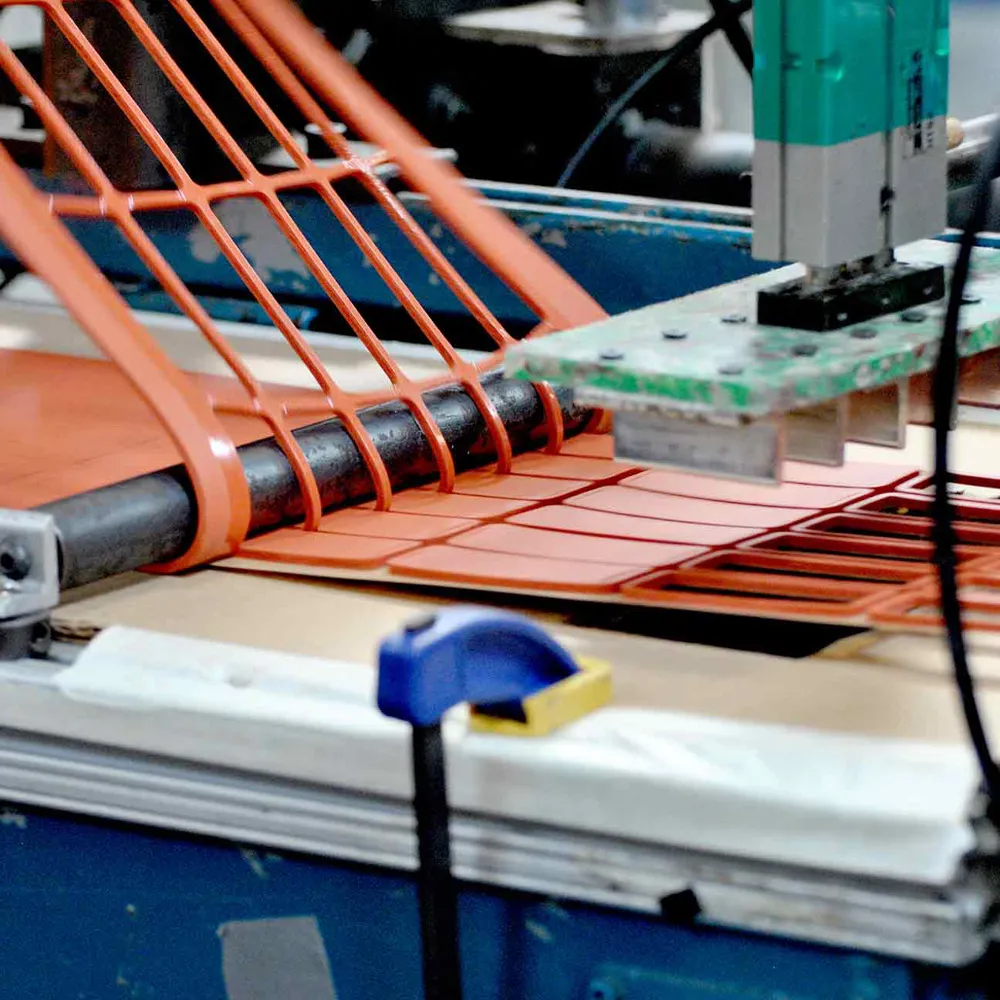

Foam & Sponge Rubber Die Cutting

JBC Technologies has more than 30 years of experience sourcing, converting, and delivering custom-engineered die cut foam and sponge rubber parts. Available in a variety of different thicknesses, densities, and chemical compositions –die cut foams and sponge rubbers are used in a wide array of automotive and industrial applications, including:

- Gasketing

- Cushioning

- Sealing

- Vibration damping

- Sound absorption

Not only will we help you identify the best foam or sponge rubber material for your die cut application, we can also help you identify the right pressure sensitive adhesive and release liner, source the materials, and surface treat, laminate, slit, and construct the composite material in house to any of our die cut rubbers and foams.

Automotive Grade Die Cut Foams

JBC laminates, slits, and die cuts automotive grade foams for a myriad of applications that range from foam trim to automotive insulation, sound absorption, cushioning, and high-grade vibration damping. Each die cut rubber and foam option offers distinct advantages based on your unique application. Let our experienced technical experts and engineers help you identify the best foam for you. Some of the automotive grade foams we work with include Armacell’s Ensolite®, Monarch®, and OleTex®, Nitto Denko’s EPT-SEALER®, Legetolex™, and SCF®, and INOAC’s Sealflex™, and CALMFLEX®.

High Temperature Die Cut Foams

JBC has extensive experience sourcing, slitting, laminating, and die cutting high temperature foams for leading manufacturers across a wide array of industries. Depending on your unique application, we offer several high temperature die cut foam options, including Silicone, Fluorosilicone, Fluorocarbon, and ECH (Epichlorohydrin).

Closed Cell Die Cut Foams

Chemical, flame, UV, and water resistant, closed cell die cut foams have strong shock absorption properties and are the ideal solution for applications that require a strong, leak-resistant moisture barrier. Compositions include Neoprene (CR), EPDM, SBR, Vinyl Nitrile, PVC, and XLPE.

Crushed EPDM/EPT

Extremely soft and highly conformable, crushed EPDM/EPT die cut foams are exceedingly common in automotive applications. They are particularly effective at sealing out water and dust in doors and windows and are a great option for applications that demand parts with resistance to weather conditions and corrosive environments.

Open Cell Die Cut Foams

Lightweight and flexible, open cell die cut foams are ideal for mitigating NVH & BSR, soundproofing, protective packaging, and applications where air and moisture permeability are needed. Compositions include Polyether (Ether), Polyester (Ester,) Reticulated, and Silicone.

Microcellular Die Cut Foams

With a low compression set, microcellular die cut foams offer a higher-performance option based on your unique application. Available compositions include Polyether (Ether), Polyester (Ester), Silicone, Urethane, high-performance Poron microcellular urethane, and ISOLOSS™ LS Polyurethane Foam, manufactured by Aearo Technologies LLC, an independent wholly owned 3M subsidiary.

Here are just a few of the many material partners we work with:

We also work with customer supplied material. If you have material that you need converted, please reach out to your sales representative or contact us for additional information.

JBC: An Experienced Foam and Rubber Die Cutting Partner

The breadth of foam and elastomeric materials available today is extensive and still growing. That’s why it’s helpful to work with a foam and rubber die cutting partner like JBC that has an extensive sourcing network, years of materials expertise, and the know-how to help guide you towards the best solution for your application. With over a hundred years of combined experience, we can help you choose the right material for the right application at the right cost.