Custom Die-Cut Gaskets, Seals, and More to reduce Automotive Buzz, Squeak & Rattle

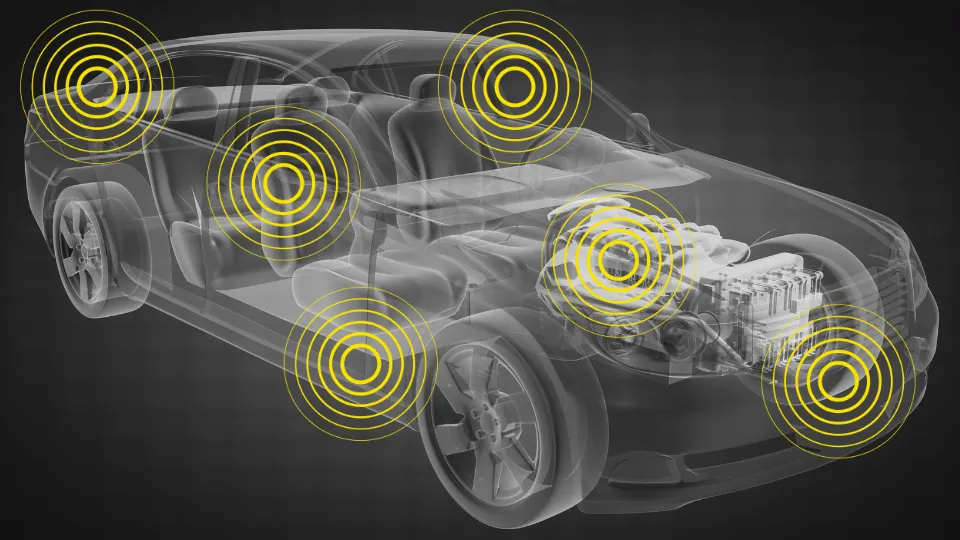

As an IATF 16949 and ISO 9001 certified flexible material converting specialist, JBC Technologies uses custom die-cutting and other vertically integrated converting processes to help automotive OEMs and tier suppliers reduce unwanted noise (aka buzz, squeak, and rattle) and control sound and vibration in their assemblies and finished products.

We do this by manufacturing custom gaskets, seals, cushions, fasteners, sound reduction panels, and other components that dampen and absorb vibrations and sound in the vehicle.

APPLICATIONS

One of the most common applications for custom die-cut parts is in the manufacture of acoustic insulation materials designed to dampen sound and vibration throughout a vehicle. By using custom die-cutting, we can convert these materials into your exact specifications, ensuring that they fit seamlessly within the various components of the vehicle. This leads to a reduction in noise and vibration levels, resulting in a quieter and more comfortable ride for drivers and passengers.

Several areas for custom die-cut components that target automotive BSR include:

- Felt strips for interior trim pieces

- Foam pads for dashboards and consoles

- Sound-deadening for speaker enclosures

- Seals and gaskets for doors and windows

- Vibration dampeners for engine components

- Anti-squeak strips for door and window frames

- Acoustic insulation pieces for doors and floors

- Adhesive-backed foam tape for securing loose parts

- Rubber bumpers for preventing rattles in moving parts

PERFORMANCE MATERIALS

JBC Technologies customers benefit from our years of experience in creating custom precision die-cut parts that meet the exacting tolerances of the automotive industry.

Here are just a few of the specialty materials we die cut that can help you reduce that annoying buzz, squeak and rattle

Foams & Sponge Rubber

Foams and sponge rubber are commonly used materials for addressing BSR issues in the automotive industry. These materials are known for their excellent sound absorption and vibration damping properties, making them ideal for use in various parts of a vehicle. Acoustic foam, for example, is a type of foam that is specifically designed to absorb sound waves and vibrations, reducing noise levels throughout the vehicle.

Foam Tapes

Foam tapes can be used to address automotive BSR issues. These tapes consist of a foam base that is coated with a layer of pressure-sensitive adhesive, which allows them to adhere to various surfaces within a vehicle. Foam adhesive tapes are commonly used in automotive applications where a soft, compressible material is needed to reduce noise and vibration levels. They can be used in various areas of a vehicle, including door panels, headliners, and floors.

Flock Adhesive Tape

Flock adhesive tape can be used to address BSR issues in the automotive industry. This material consists of a foam or rubber base that is coated with a layer of flocking, which is a type of fiber that is applied using an electrostatic process. Flock adhesive tape is commonly used in automotive applications where a soft, non-abrasive surface is needed to reduce noise and vibration levels. It can be used in various areas of a vehicle, including door panels, headliners, and dashboards.

Acrylic Foam Tapes

Acrylic foam tapes are used for permanent bonding and fastening in many automotive applications—from attaching logos, trim and extrusions to bonding lenses and touch panels in automotive electronics. They have a highly viscoelastic foam core that can absorb energy and relax stress. And their 100% bond strength means you won’t experience the shaking or rattling you get with mechanical fasteners that come loose.

Your Partner. For Die-Cut Solutions to Buzz, Squeak, and Rattle

Whether your noise solution happens to be an adhesive-backed open or closed cell foam gasket, a custom microcellular polyurethane seal or cushion, a precision die cut acrylic foam tape, or something else entirely, you can count on JBC Technologies for high quality fabrication of cost effective noise and vibration reduction solutions.

Contact us today to learn more about our custom die-cut solutions for automotive BSR.