Pressure-Sensitive Adhesives Transfer Tapes for Custom Die-Cutting

JBC Technologies is a 3M™ Preferred Converter with extensive manufacturing and die-cutting capabilities. We are a premier converter of adhesive transfer tapes for OEMs and Tier 1 suppliers in a wide variety of markets. Industry use cases range from electronic components and displays to membrane switches, automotive, appliances, medical devices, HVAC, and more.

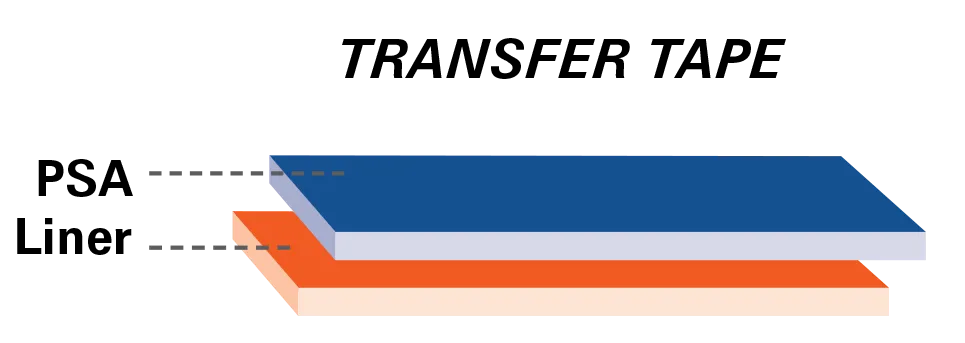

What is Adhesive Transfer Tape?

Adhesive transfer tape is one of the most common types of tape we convert at JBC Technologies. Unlike a double-coated tape, which has a carrier lined on either side with an adhesive, transfer tapes have no carrier. The rubber or acrylic-based pressure-sensitive adhesive is coated onto a removable release liner, typically made of film or paper. Transfer tapes are typically thinner than double-coated tapes, but because there is no carrier, they tend to be more conformable.

Types of Transfer Tape

As with double-coated tapes, there are many different types of transfer tapes with both permanent and removable bonds, all applicable for different situations. Examples include:

- Medical Adhesive Transfer Tape

- High-Performance Adhesive Transfer Tape

- Optically Clear Transfer Tape

- High-Temperature Transfer Tape

- Low Surface Energy Transfer Tape

- Very High Bond Transfer Tape

- Double Linered Adhesive Transfer Tape

How Does Adhesive Transfer Tape Differ from Double-Coated Tape?

When compared to double-coated tapes, transfer tapes tend to be thinner, more conformable, and more apt to perform at higher temperatures.

Watch this helpful video from 3M to learn more

Why JBC Technologies ?

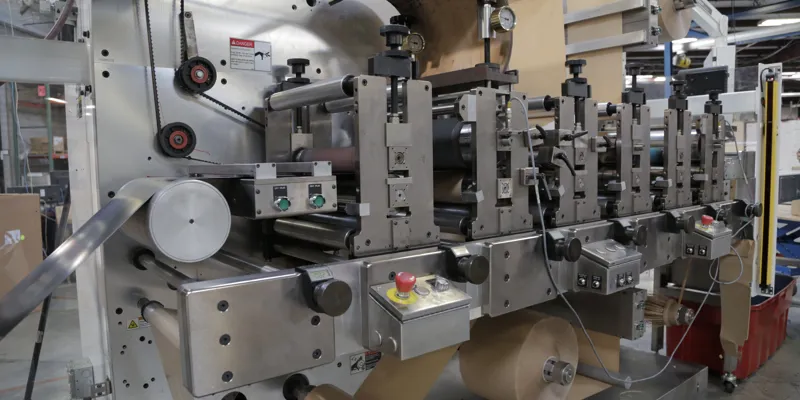

With over 30 years of industry experience and a wide range of flexible materials converting equipment that includes high-speed, tight-tolerance rotary presses, hot and cold melt laminators, and narrow and wide web hydraulic press machines, JBC Technologies is your one-stop resource for custom die-cut parts. Couple our manufacturing capabilities with our extensive team of knowledgeable and experienced process engineers and our decades-long strategic partnerships with some of the best adhesive transfer tape manufacturers in the industry, and it’s easy to see why JBC Technologies leads the way in custom die-cutting solutions.

Partner with a 3M™ Preferred Converter You can trust

JBC Technologies is a leading die-cut manufacturer and flexible material converter, providing custom parts to OEMs and industrial suppliers for more than 30 years. When you work with JBC, you can count on us to take an unbiased and collaborative approach to developing the best, most cost-effective solution for your die cut products.

Ready to see how creative flexible material converting can benefit your business?