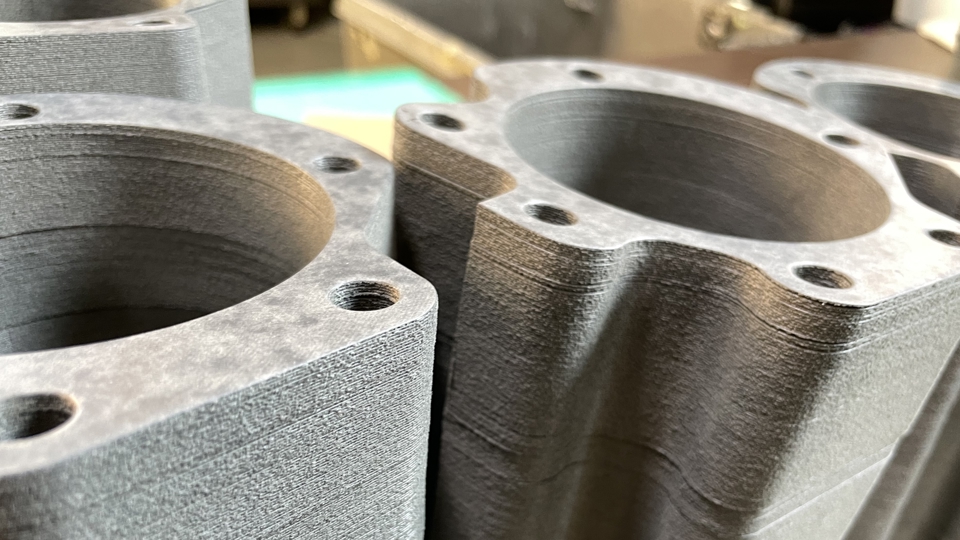

Die Cut Pressure Seals for Flanged Connections

Die cut pressure seals are used with pumps, compressors, and fluid power components in hydraulic and pneumatic systems. They’re made of non-metallic materials and create a static seal between two flange faces. By filling the tiny gaps and surface irregularities between the flange faces, die cut pressure seals help contain pressurized liquids or gases. In applications such as oil and gas exploration, die cut flange gaskets may be subjected to high pressures and temperatures.

Die Cut Pressure Seal Design

For engineers, designing a pressure seal requires understanding of all the application requirements. In addition to maximum pressure and temperature, it’s important to account for other key operating conditions. For example, what is the full range of pressures and temperatures? What is the type of fluid that requires containment, and is this fluid acidic or basic? Viscosity, a measure of resistance to flow, is also worth considering. Heavy crude oil doesn’t flow easily, and requires greater pressurization.

Die Cut Pressure Seal Materials

Typically, pressure seals for flanged connections are die cut from sheet materials such as aramid fiber, glass fiber, elastomers, graphite, and PTFE or Teflon®. By comparing your requirements with a material’s properties, you can make the right choice based on application conditions. With softer materials such as elastomers, it’s also important to consider the durometer (hardness) and the compression set, the permanent deformation (sometimes called memory) that remains when an applied force is removed.

Types of Die Cut Pressure Seals

Die cut pressure seals for flanged connections include two types of flat gaskets: full-face and flat-ring. Both are defined in ASTM B16.21, which also specifies gasket materials, dimensions, and dimensional tolerances. Full-face gaskets are used with flat-faced flanges and support bolt patterns such as 4, 8, 12, and 16-bolt flange. Flat ring gaskets are designed for flanges with a raised face. These die cut pressure seals don’t have bolt holes, but flange deflections squeeze the gasket and cause permanent deformation.

Because they’re circular and have an opening in the center, full-face and flat-ring gaskets resemble O-rings. Despite these similarities, the seal types are not identical. O-rings are donut-shaped with rounded or contoured edges. By contrast, full-face and flat-ring gaskets are characterized by “square edges” where the two planes intersect at a 90-degree angle. In layman’s terms then, a flat gasket looks like a metal washer rather than a donut. Plus, O-rings are used in grooves rather than with flat or raised surfaces.

Custom Die Cutting for Pressure Seals

Do you need die cut pressure seals for flanged connections such as pumps or compressors? For over 25 years, JBC Technologies has been a leader in customized die cutting solutions for industrial companies. For more information about our custom die cutting capabilities pressure seals, high-temperature gaskets, and chemical-resistant gaskets, contact us.