Stronger Together: Key Multi-Laminate Materials for Improving Battery Lifespan and Durability

There is no one "perfect" material...

Within the burgeoning battery space, it can sometimes feel like the wild west when it comes to materials -- there is no one “silver bullet” for solving many battery challenges. The "perfect" solution often lies at the intersection of multiple performance materials and enhanced converting capabilities.

Multi-layer laminates are a key way to maximize the functionality of a component without adding excess weight or bulk. Using innovative die-cutting and converting technologies, multiple performance materials can be laminated together in-line to create a high-performance multi-faceted solution in a smaller, more efficient form factor, helping pass cost savings down to the end user.

Today, we’ll be highlighting three key examples of material combinations that boost battery lifespan and durability by providing thermal management, mechanical protection, and environmental barriers, as well as highlighting the converting technology behind them.

It's important to note that while the following material combinations are examples of possible material solutions to these challenges, they are not one-size-fits-all. Consult with a converting partner to select what's right for your project.

Okay, now let's dive in...

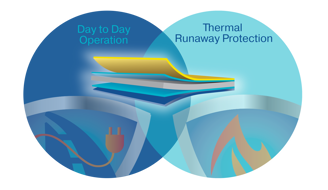

Thermal Management and Stability

Localized hot spots and extreme temperature fluctuations can significantly accelerate battery degradation if left unaddressed. This first performance composite aims to solve that and more with its heat spreading and electrically insulative properties...

Flexible Graphite + Polyimide Film + PSA

How it works: Flexible graphite is an excellent lightweight heat spreader on its own, but lacks any electrically insulating properties. Pair this with a thin dielectric film like Polyimide and stick it using a PSA to create a multi-functional component that efficiently pulls heat from hotspots while guaranteeing a primary layer of electrical insulation. And it sticks just about anywhere -- metal busbars, module walls, around sharp cell corners, you name it! This is three distinct solutions with the internal battery/pack footprint of one.

On top of adding dielectric protection and adhesion, the addition of these two functional layers also provides encapsulation. For inherently dusty materials, like graphite, encapsulation is key for preventing contamination and improving the longevity of the component.

|

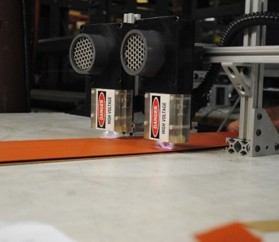

How we do it: As a vertically integrated converter, we can laminate and die-cut materials in line on our Delta Crusader rotary die-cutting presses. The Delta Crusader is a multi-station servo-driven rotary press that allows for enhanced tension control, leading to improved dimensional stability. The ability to laminate and cut materials in-line helps us do more with a single machine pass, helping streamline production and drive down costs. |

|

|

|

JBC's Delta Crusader in action, die-cutting flexible graphite. |

Mechanical Protection and Stress Management

There are many high-performance materials for addressing vibration, shock, cell expansion, and other mechanical challenges within battery packs, including silicone foams, microcellular urethanes, and high-performance films like PET, Polypropylene, and Polycarbonate. Let’s look at a multi-laminate option for this as well...

Silicone urethane foam + PET Film + Differential Double-Sided PSA

How it works: The silicone foam provides a constant push-back force on each cell, providing necessary compression and vibration dampening. This, combined with a puncture-resistant PET film, protects the foam from sharp edges, burns, or cuts on the metal housing. In this scenario, you get high-performance cell compression that won’t be damaged under the stresses of typical use. The differential double-sided PSA allows the component to be repositioned during the initial placement and to bond more easily to dissimilar surfaces (i.e. the PET and the metal housing).

|

How we do it: For bonding two dissimilar low-surface energy materials like silicone foam and a PET film, JBC leverages our enhanced laminating capabilities, which include inline surface treatment. Our inline coroner treater energizes the surface of these hard-to-stick materials, creating active sites that allow for better bonding. For modern battery packs where many dissimilar materials often meet, this is an invaluable process. So, what does this mean? This means JBC can surface treat, laminate, and die-cut multiple materials in one pass on a single machine. |

|

|

Check out the blue-purple glow of the plasma exciting the material in this close-up! |

Environmental Barriers

While not as “sexy” as the other solutions, the reliability and durability of battery packs heavily rely on their ability to resist environmental elements. This category mostly focuses on high-performance gaskets, seals, and protective layers that keep unwanted elements out of sensitive battery compartments. This includes Closed-cell foams and high-performance films. For our last composite, we're covering a combination that works together to prevent all kinds of environmental ingress.

Closed-Cell EPDM Foam + Chemically Resistant Film + PSA

How it works: The closed-cell foam provides an environmental seal that prevents air, dust, moisture, and other ingress. The outer PTFE film adds chemical resistance against electrolytes, road salts, and cleaning agents. Now, we have a gasket or seal that can protect against pretty much all types of contaminants/environmental ingress, keeping the battery clean, safe, and dry.

|

How we do it: For more complex components, JBC leverages our enhanced capability rotary die-cutting machines, like our 10-inch 10-station Dorey Converting Machine (DCS) or our 18-station HOACO rotary machine. Both of these servo-driven presses provide the same control as our smaller Delta Crusader machines, but their large size gives us much more flexibility and capability to do more in a single pass, yielding more complex technical parts with greater ease and efficiency. The end result? Increased production efficiency and lower manufacturing costs. |

|

|

Pictured here is our mammoth HOACO 18-Station Rotary Machine. |

JBC Technologies: Keeping Up with the Speed of Innovation

With the rate that battery technology is advancing, you need an agile partner with the technical know-how and industry connections to help you keep up.

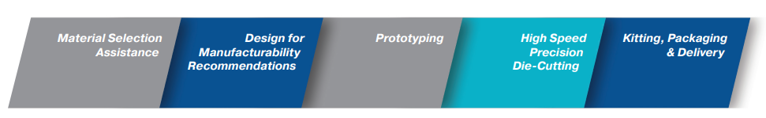

JBC Technologies has over 35 years of experience providing die-cut solutions to the battery and energy storage, automotive, aerospace, medical, and industrial markets. With a team of degreed engineers and a wide range of converting capabilities across four U.S.-based locations, JBC is an invaluable partner for thermal and electrical management, gaskets, seals, and insulation solutions. Founded on the pillars of supply chain optimization, engineering innovation, and manufacturing excellence, JBC provides full product lifestyle support, from low-volume prototyping to high-volume production.