Performance Materials for Die Cutting Sponge & Foam Rubber Material Data Sheets

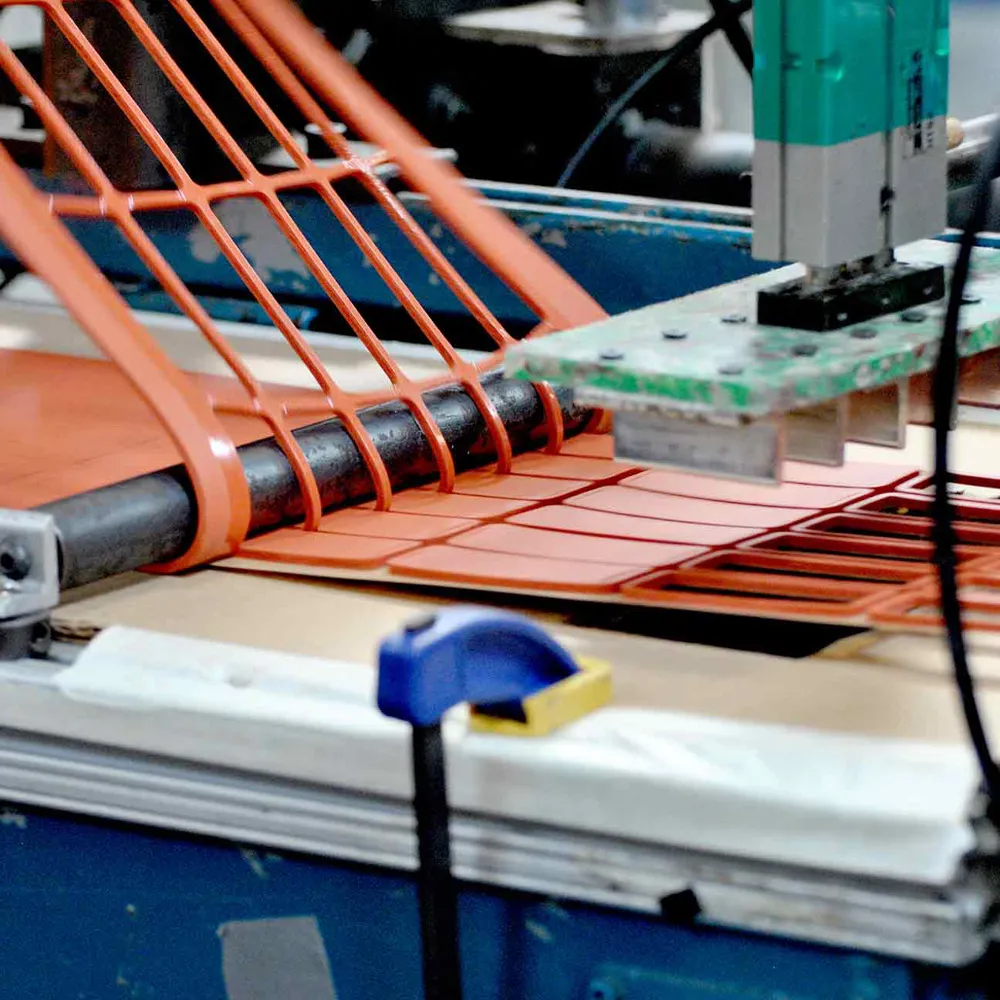

Foam and sponge rubber are some of the most common materials for die cutting to make gaskets and seals, and over the last 30 years, we've probably worked with just about all of them.

JBC uses specialty converting processes, including lamination, slitting, and precision die-cutting, to transform a wide variety of different foam and rubber materials into custom die-cut parts for our customers worldwide. Our customers use these parts in markets like medical and automotive and for various applications like anti-vibration and cushioning.

If you're looking for foam and sponge rubber material data sheets, you've come to the right place. Browse below by manufacturer and then scroll through their products to find the link for the appropriate material data sheet. View and download or let us know if you have questions.

3M™ ISOLOSS™ LS Polyurethane Foam

ISOLOSS LS foams are manufactured by Aearo Technologies LLC, an independent, wholly-owned subsidiary of 3M. ISOLOSS LS is a family of durable, all-purpose microcellular polyurethane foams that are ideal for energy absorption, cushioning, gasketing, and sealing applications that require a low compression set and consistent force deflection. Common use cases include:

Heavy Equipment • Appliances • HVAC • General Industrial • Medical Equipment • Automotive Exterior • Hard Goods • Electronics • Power Generation

3M ISOLOSS foams are UL-rated and come in bulk rolls for easier converting. ISOLOSS LS foams are also available in a wide range of standard thicknesses (0.03 in to 0.5 in) and in (4) standard density/Durometer options - 10 lbs/ft3, 15 lbs/ft3, 20 lbs/ft3, and 25 lbs/ft3.

armacell EnsoLite Elastomeric Closed-Cell Foams

The armacell EnsoLite product line offers a broad range of closed-cell and semi-closed-cell foam products based on PVC/NBR, PVC/NBR/CR, EPDM, and Neoprene for applications in the industrial and automotive markets. The continuous-roll stock provides economies in fabrication. The EnsoLite product line also offers a complete range of density and compression deflection ranges.

Elastomeric Component Foam (ECF) products like EnsoLite have been tested to various standards and meet many automotive, military, or industrial standards.

armacell EnsoLite | EF0 Crushed EPDM Foam Rubber

Armacell Ensolite EF0: Armacell LLC is a black, very soft, semi-open / fine cell, “crushed” EPDM with a density of 4 - 8 lb./ft3 (64 - 128 kg/m3) and typical 25% compression deflection values of 1.0 psi (6.9 kPa) max. EF0 can be graded as an ASTM D 1056-07 1A0 and SAE J-18 APR2002 1A0 cellular product with one exception to the basic requirements (compression set at elevated temperature).

EF0 meets the flame resistance requirements of FMVSS-302 at 1/8” (0.125”) (3.17 mm) and higher. EF0 is UL listed to UL 94 V-0, 5VA, and HF-1 at specific thicknesses (request additional information). EF0 meets all the requirements of Toyota TSK 6505G-05 Class 2A.

armacell Ensolite | IV1 PVC/NBR/CR Foam Rubber

A black, continuous, closed-cell, medium-density 3 to 5 lb/ft3 (48 to 80 kg/m3) PVC/NBR/CR rubber foam in roll form that is ideal for gaskets or other sealing applications in environments with a high intermittent service temperature of 200°F (93.3°C). Available in a range of thicknesses and roll sizes.

armacell Ensolite | IV2 PVC/NBR/CR Foam Rubber

A black, continuous, closed-cell, medium-density (5.5-7.5 lb/ft3) (88-120 kg/m3) PVC/NBR/CR rubber foam in roll form that is ideal for gaskets or other sealing applications in environments with a high intermittent service temperature of 200°F (93.3°C). Available in a range of thicknesses and roll sizes.

armacell Ensolite | IV3 PVC/NBR/CR Foam Rubber

A black, continuous, closed-cell, medium-density (7.0-9.5 lb/ft3) (112-152 kg/m3) PVC/NBR/CR rubber foam in roll form that is ideal for gaskets or other sealing applications in environments with a high intermittent service temperature of 200°F (93.3°C). Available in a range of thicknesses and roll sizes.

armacell Monarch 2002 | Neoprene Foam Rubber

A black closed-cell 9±2 lb/ft3 (144±32 kg/m3) Neoprene based rubber foam in bun form engineered for automotive applications in environments with a continuous operating temperature of up to 150°F (65.6°C).

armacell Monarch 3061 | 100% EPDM Foam Rubber

armacell® Monarch® 3061 is a black, closed cell, 3 - 5 lb/ft3 (48 - 80 kg/m3 ) density, 100% EPDM foam rubber that meets ASTM D 1056 2A1and FMVSS 302 at a minimum thickness of 3/16" (0.1875") (4.76 mm) and higher. Monarch® 3061 has excellent resistance to ozone and elevated temperatures and is UL listed to UL50E [periodic & continuous compression], UL48 & UL508 (UL File#: JMLU2.MH25062). armacell® Monarch® 3061 is an approved source for GMW 17408 Class I Type IV.

armacell Monarch 3092 | EPDM Foam Rubber

A black closed-cell 5±1 lb/ft3 (80±16 kg/m3) EPDM based rubber foam in bun form engineered for automotive applications in environments with a continuous operating temperature of up to 220°F (104.4°C).

armacell Monarch 4053 | Epichlorohydrin (ECH) Foam Rubber

armacell® Monarch® F-4053 is a black, closed cell, 18±3 lb/ft3 (290±48 kg/m3) density, epichlorohydrin (ECH) rubber product in bun form engineered for automotive applications in environments with an operating temperature range of -40F to 300°F (-40°C to 148.9°C). Passes FMVSS-302.

armacell Monarch 5013 | EPDM/Neoprene/SBR Blended Foam Rubber

A black, closed cell, 9±2 lb/ft3 (144±32 kg/m3) density, EPDM/Neoprene/SBR blended rubber product in bun form engineered for automotive applications in environments with a continuous operating temperature of up to 200°F (93.3°C). Also available in gray.

armacell Monarch 5031 | EPDM/Neoprene/SBR Blended Foam Rubber

A black, closed cell, 6±2 lb/ft3 (96±32 kg/m3) density EPDM/Neoprene/SBR blended rubber product in bun form engineered for general purpose applications in environments with a continuous operating temperature of up to 200°F (93.3°C). Also available in gray.

armacell Monarch 5032 | EPDM/Neoprene/SBR Blended Foam Rubber

A black, closed cell, 6±2 lb/ft3 (96±32 kg/m3) density EPDM/Neoprene/SBR blended rubber product in bun form engineered for general purpose applications in environments with a continuous operating temperature of up to 200°F (93.3°C). Also available in gray and dark black.

armacell Monarch 5522 | EPDM/Neoprene/SBR Blended Foam Rubber

A white, closed cell, 6±2 lb/ft3 (96±32 kg/m3) density EPDM/Neoprene/SBR blended rubber product in bun form engineered for general purpose applications in environments with a continuous operating temperature of up to 200°F (93.3°C).

armacell Monarch 5913 | EPDM/Neoprene/SBR Blended Foam Rubber

A gray, closed cell, 9±2 lb/ft3 (60±5 kg/m3) density EPDM/Neoprene/SBR blended rubber product in bun form engineered for general purpose applications in environments with a continuous operating temperature of up to 200°F (93.3°C).

armacell Monarch 5932 | EPDM/Neoprene/SBR Blended Foam Rubber

A gray, closed cell, 6±2 lb/ft3 (96±32 kg/m3) density EPDM/Neoprene/SBR blended rubber product in bun form engineered for general purpose applications in environments with a continuous operating temperature of up to 200°F (93.3°C).

armacell Monarch 8062 | 100% EPDM Foam Rubber

armacell® Monarch® 8062 is a pure EPDM medium-soft, closed-cell expanded foam rubber with a density of 8±2 lb/ft3 (128±32 kg/m3) and a maximum continuous use temperature rating of 220°F (104.4°C). Monarch 8062 is available in blocks and buns only and is FMVSS-302 rated and UL 50E listed. Excellent heat and temperature resistance and commonly used for gaskets, sealing, and shock absorption applications.

Gaska® V700 Series

A black, light-density (7 lb/ft3)(112 kg/m3) closed-cell polyvinyl chloride (PVC) foam designed for use in applications requiring positive seals on irregular surfaces or when flex and conformability are critical. For use in environments with temperatures of up to 180°F (82.2°C). Other colors available upon request.

Available Thicknesses

V710 0.079 – 1.00 in (2.0 – 25.4 mm)

V715 0.094 – 0.500 in (2.4 – 12.7 mm)

Available Widths

0.250 – 57 in (6.4 – 1,448 mm)

Available Lengths

10 – 302 ft (3 – 92 m)

Gaska® V800 Series

A gray, light-density (8 lb/ft3)(128 kg/m3) closed-cell polyvinyl chloride (PVC) foam designed for use in applications requiring positive seals on irregular surfaces or when flex and conformability are critical. For use in environments with temperatures of up to 180°F (82.2°C). Other colors available upon request.

Available Thicknesses

V810 0.079 – 1.00 in (2.0 – 25.4 mm)

V815 0.094 – 0.500 in (2.4 – 12.7 mm)

Available Widths

0.250 – 57 in (6.4 – 1,448 mm)

Available Lengths

15 – 302 ft (4.6– 92 m)

Gaska® V1100 Series

A gray, medium-density (11 lb/ft3)(176 kg/m3) closed-cell polyvinyl chloride (PVC) foam. Provides an excellent combination of flexibility and conformability with strength and wear resistance. Performs in those “tough duty” applications where a tape must still flex to fit and seal. For use in environments with temperatures of up to 200°F (93.3°C). Other colors available upon request.

Available Thicknesses

V1110 0.063 – 0.50 in (1.6 – 12.7 mm)

V1115 0.079– 0.250 in (2.4 – 12.7 mm)

Available Widths

0.250 – 57 in (6.4 – 1,448 mm)

Available Lengths

25 – 302 ft (7.6– 92 m)

Gaska® V1500

A gray, medium-density (15 lb/ft3)(240 kg/m3) closed-cell polyvinyl chloride (PVC) foam. Provides an excellent combination of flexibility and conformability with strength and wear resistance. Performs in those “tough duty” applications where a tape must still flex to fit and seal. For use in environments with temperatures of up to 200°F (93.3°C). Other colors available upon request.

Available Thicknesses

V1510 0.063 – 0.500 in (1.6 – 12.7 mm)

V1515 0.063– 0.313 in (1.6 – 4.8 mm)

Available Widths

0.250 – 57 in (6.4 – 1,448 mm)

Available Lengths

25 – 302 ft (7.6– 92 m)

Gaska® V2500

A black, high-density (25 lb/ft3)(400 kg/m3) closed-cell polyvinyl chloride (PVC) foam. Designed for use in the most demanding foam sealing or cushioning applications. High internal strength resists pressure from outside forces and high hardness resists deterioration. For use in environments with temperatures of up to 200°F (93.3°C). Other colors available upon request.

Available Thicknesses

V2510 0.031 – 0.250 in (0.8 – 6.4 mm)

V2515 0.039– 0.188 in (1.0 – 4.8 mm)

Available Widths

0.250 – 57 in (6.4 – 1,448 mm)

Available Lengths

25 – 302 ft (7.6– 92 m)

INOAC Gomspor C-4305

A gray medium-density (12 lb/ft3)(190 kg/m3) chloroprene rubber foam with mid-level hardness (Shore C 17) available in both block and sliced sheet form. Possesses excellent chemical resistance and is self-extinguishing making it useful for applications where flame retardant behavior is important. Suitable for gaskets and seals in environments with a maximum temperature of 200°F (93.3°C).

INOAC Gomspor C-4315

A gray medium-density (12 lb/ft3)(190 kg/m3) chloroprene rubber foam with mid-level hardness (Shore C 24) available in both block and sliced sheet form. Possesses excellent chemical resistance and is self-extinguishing making it useful for applications where flame retardant behavior is important. Suitable for gaskets and seals in environments with a maximum temperature of 200°F (93.3°C).

K-FLEX® DUCT® Liner - Gray

A gray NBR/PVC-based closed cell, flexible elastomeric foam thermal and acoustic insulation designed to reduce sound transmission and/or retard heat gain/loss and prevent condensation when used as an internal liner on ductwork or equipment. Recommended maximum operating temperature is 220°F (104°C). Available in thicknesses of ½-in (1.27-cm) up to 2-in (5.1-cm) with an average density of 4.5 lbs/ft3 (172.1 kg/m3).

Also available with factory applied pressure-sensitive adhesive (PSA) backing.

K-FLEX® INSUL-SHEET®

An environmentally friendly NBR/PVC-based closed cell, flexible elastomeric black foam insulation available in flat sheet or roll form in thicknesses of 1/8” up to 2” (3.175 to 50.8 mm). Recommended for applications with service temperatures ranging from -297°F (-182°C) to +220°F (+104°C). Used to retard heat gain and prevent condensation or frost formation on below-ambient applications, including utility and industrial process equipment, tanks, vessels, ducts and large OD pipes.

Also available with factory applied pressure-sensitive adhesive (PSA) backing - INSUL-SHEET® PSA.

K-FLEX® K-FONIK® AB

An environmentally-friendly CFC-free, flexible open cell sheet comprised of recycled, closed cell foam bonded together by a urethane adhesive. Effectively reduces sound reflection and transfer and is commonly used for acoustic damping, gasketing and thermal insulation. Available in thicknesses of ½-in (1.27-cm) up to 2-in (5.1-cm). Recommended maximum operating temperature is 185°F (85°C). Available in thicknesses of ½-in (1.27-cm) up to 2-in (5.1-cm) and in densities of 10 & 15 lbs/ft3 (160 kg/m3).

K-FLEX® K-FONIK® GK-GV

Environmentally-friendly black (GK) and gray (GV) flexible noise barriers constructed of non-reinforced, resilient mass-loaded elastomeric materials. GK and GV are both made with fire resistant mineral fillers and are 25/50-rated when tested to ASTM E 84 standards. GV also complies with ASTM E 162, ASTM E 662 and IMO A 653 (CE Marine).

Monmouth Durafoam™ P493SHD 100% EPDM Rubber

Monmouth Durafoam P493SHD is a black high-performance 100% EPDM Rubber with a density range of 16-25 lbs/ft3 (256.3-400.5 kg/m3) and a maximum operating temperature of 300°F (148.9°C).

Monmouth Durafoam™ Closed Cell Epichlorohydrin (ECH) Foam

Monmouth Durafoam™ Closed Cell Epichlorohydrin (ECH) Foam is a series of black, 100% ECH rubber foams with a density range of 15-23 lbs/ft3 (240.3-368.4 kg/m3) and a temperature use range of -40°F - +325°F (-40°C to 162.7°C).

C41 ECH • C42 ECH • C43 ECH • C44 ECH • C45 ECH

Monmouth Durafoam™ DK Series | NEO/EPDM Closed-Cell Blend Foam Rubber

The Monmouth Durafoam DK Series features a black NEO/EPDM blend foam rubber that is UL recognized in all thicknesses, including

- UL 50E – Std safety for enclosures for electrical equipment

- UL 508 – Std for safety industrial control equipment

- UL 157 – Std for the safety of gasket and seals

- UL 94 HF1 – Std for safety for test for flammability for plastic materials

Available in densities from 6 lbs/ft3 to 13 lbs/ft3 (96 kg/m3 to 208 kg/m3). Good for use in temperatures from -40°F to +250°F (-40°C to 121°C) with excellent chemical, oil, and flame resistance.

Nitto 685L Series (Super Soft EPT Foam Sealer)

A black low to medium-density (6.2 - 10.0 lb/ft³) (100 - 160 kg/m³) expanded semi-closed cell EPDM synthetic rubber designed for for use in a variety of high performance gasketing and insulation applications. Available in rolls or sheet form in thicknesses ranging from 0.079 to 1.2-in (2 to 30 mm) with two types of PSA backing (acrylic and butyl). Maximum continuous operating temperature 250°F (121°C).

Nitto EPTSEALER EC-100 Series

Flexible EPDM rubber foam sealing material with a semi-closed cell structure ideal for waterproofing, airtightness, soundproofing, or thermal insulation. All EC-100 series products contain a chlorine-free flame retardant and meet the requirements for UL-94 and HF-1 certification. Available as foam-only in thicknesses from 3 - 10 mm (0.12 - 0.78 in) and in several standard adhesive/backing combinations.

Nitto EPTSEALER EC-200 Series

Flexible EPDM rubber foam sealing material with a semi-closed cell structure ideal for waterproofing, airtightness, soundproofing, or thermal insulation. All EC-200 series products contain a flame retardant and meet the requirements for UL-94HBF certification. Available as foam-only in thicknesses from 3 - 10 mm (0.12 - 0.78 in) and in several standard adhesive/backing combinations.

Nitto EE-1000L Series (Super Soft EPT Foam Sealer)

A black, low-density (5 - 9 lb/ft³) (80 - 150 kg/m³) expanded, semi-closed cell EPDM synthetic rubber designed for for use in a variety of high performance gasketing and insulation applications. Available in rolls or sheet form in thicknesses ranging from 0.118 to 1.2-in (3 to 30 mm) with two types of PSA backing (acrylic and butyl). Maximum continuous operating temperature 250°F (121°C).

Nitto EPTSEALER EH-2200 Series

A flexible EPDM rubber foam sealing material with a semi-closed cell structure with excellent weather, heat and chemical resistance. Ideal for use as a buffer, dustproofing/soundproofing, and thermal insulation Available as foam-only in thicknesses from 3 - 10 mm (0.12 - 0.78 in) or with an acrylic adhesive and non-woven fabric backing.

Nitto EV-1000L Series (Low VOC - Super Soft EPT Foam Sealer)

A low VOC, black, low-density (4.1 - 5.9 lb/ft³) (65 - 100 kg/m³) expanded, semi-closed cell EPDM synthetic rubber designed for for use in a variety of high performance gasketing and insulation applications. Available in rolls or sheet form in thicknesses ranging from 0.118 to 1.2-in (3 to 30 mm) with two types of PSA backing (acrylic and butyl). Maximum continuous operating temperature 250°F (121°C).

Nitto SCF100 Series (Super Clean Foam)

A series of high-purity polypropylene (PP) foam materials with a unique micro-cell structure that makes them an excellent choice for further processing (i.e. rotary and semi-automatic die-cutting). Available in thicknesses from 0.5 – 1 mm (0.02 - .039 in) with or without acrylic adhesive. Designed for use mainly in electronic devices as a dust-proof seal, buffer, shock absorber, and light shield.

Fuzion™ Cross-Linked Polyethylene (XLPE) Foam

Fuzion™ Cross-Linked PE (XLPE) rolls from Palziv North America offer superior consistency and performance. Fuzion™ rolls are lightweight, waterproof, and shock absorbent, and come in a wide variety of densities, roll widths, custom roll lengths, and colors to satisfy your specific application.

Standard colors for Fuzion™ Cross-Linked PE foam are gray, black, and natural. Also available in Soft (SEV) and Ultra-Soft (UEV), fire retardant, custom colors, ultraviolet inhibitors, antistat, conductive, and static dissipative.

|

|

Novagard® General Purpose PVC Foam

The Novagard® Foam Seal line of general purpose industrial-grade PVC foams provides an economical solution to your most demanding sealing and cushioning requirements. These closed-cell PVC foams can be manufactured with or without a water-based acrylic adhesive and come in a variety of colors, thicknesses, densities and roll lengths. Not recommended for continuous use at temperatures above 180°F (82°C).

- Foam Seal Sof-Seal - A super-soft industrial PVC foam for use in applications that require low force to compress.

- (5.5 - 9 lbs/ft3)(88- 144 kg/m3)

- Foam Seal Low-Density - An economical general purpose soft foam for use in applications requiring a seal for tight radius curves

- (5.5 - 10 lbs/ft3)(88- 160 kg/m3)

- Foam Seal Medium-Density - For applications requiring a combination of flexibility and strength. Medium Density foam permits clean die cuts and fastener penetration.

- (9 - 13 lbs/ft3)(144 - 208 kg/m3)

- Foam Seal High-Density - For applications requiring a cushion against heavy loads. Withstands wear and abrasion in “tough duty” applications.

- (13 - 17 lbs/ft3)(208 - 272 kg/m3)

- Foam Seal Very High Density - For applications requiring a cushion against very heavy loads. Withstands wear and abrasion in heavy-duty applications.

- (17 - 21 lbs/ft3)(272 - 336 kg/m3)

Novagard® Foam Seal 60A

A black, flexible, low-density (≈5.8 lbs/ft3)(≈93 kg/m3) automotive grade PVC foam formulated to conform to the multiple automotive material specifications. Designed as a soft foam for applications with a low force to compress and for filling large voids and variable gaps. Available in a range of thicknesses from 0.0625 - 0.75-in (1.59 - 19.05-mm) and not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal 60-HTA

A black, flexible, low-density (9-13 lbs/ft3)(144 - 208 kg/m3) automotive grade PVC foam formulated specifically to conform to the requirements as outlined in the GMW 17408 Class II Type II (interior/exterior applications) and GMW 17408 class IV, Type II specifications. Designed as a soft foam for applications with a low force to compress and for filling large voids and variable gaps. Available in a range of thicknesses from 0.0625 - 0.75-in (1.59 - 19.05-mm) and not recommended for continuous use at temperatures above 180°F (82°C)

Novagard® Foam Seal 70P UL HF-1/HBF

A black, flexible, low-density (6.2 - 10 lbs/ft3)(99.3 - 160.2 kg/m3) industrial grade PVC foam formulated formulated to conform to UL HF1/HBF and is a recognized component of Underwriters Laboratories®. Designed as a soft foam for applications with a low force to compress and for filling large voids and variable gaps. Available in a range of thicknesses from 0.0625 - 0.75-in (1.59 - 19.05-mm) and not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal 100 HTA

A black, flexible, low-density (9-13 lbs/ft3)(144 - 208 kg/m3) automotive grade PVC foam formulated specifically to conform to the requirements as outlined in the GMW 17408 Class II Type III (interior/exterior applications) and GMW 17408 class IV, Type III specifications. Designed as a soft foam for applications with a low force to compress and for filling large voids and variable gaps. Available in a range of thicknesses from 0.0625 - 0.75-in (1.59 - 19.05-mm) and not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal 150 HTA

A black, flexible, medium-density (13 - 17 lbs/ft3)(208 - 272 kg/m3) automotive grade PVC foam formulated specifically to conform to the requirements as outlined in the GMW 17408 Class II Type IV (interior/exterior applications) and GMW 17408 class IV, Type IV specifications. Designed for applications requiring a cushion against heavy loads. Withstands wear and abrasion in “tough duty” applications. Available in a range of thicknesses from 0.0625 - 0.75-in (1.59 - 19.05-mm) not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal Aluma-Seal

A black, flexible, medium-density (9 - 13 lbs/ft3)(144 - 208 kg/m3) industrial grade PVC foam cast on an aluminum liner. Typically used as an insulator, it prevents condensation build-up on surfaces to which it is applied. Reduces vibration and deadens sound in HVAC applications. Available in a range of thicknesses from 0.0625 - 0.75-in (1.59 - 19.05-mm) not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal Aluma-Seal Low Density

A black, flexible, low-density (5.5 - 9 lbs/ft3)(88- 144 kg/m3) industrial grade PVC foam cast on an aluminum liner. Typically used as an insulator, it prevents condensation build-up on surfaces to which it is applied. Reduces vibration and deadens sound in HVAC applications. Available in a range of thicknesses from 0.0625 - 0.75-in (1.59 - 19.05-mm) not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal Aluma Seal 94

A black, flexible, low-density (6.2 - 10 lbs/ft3)(99 - 160 kg/m3) industrial grade PVC foam cast on an aluminum liner formulated to conform to UL 94 HF1/HBF and is a recognized component of Underwriters Laboratories®. Typically used for appliances, pipes, and pans to prevent condensation build-up on surfaces. Available in a range of thicknesses from 0.0625 - 0.5-in (1.59 - 12.7-mm) not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal Aluma Seal 723

A black, flexible, low-density (6 - 9 lbs/ft3)(96 - 144 kg/m3) industrial grade PVC foam cast on an aluminum liner. This product is UL 723 classified. Typically used as an insulator, it prevents condensation build-up on surfaces to which it is applied. Reduces vibration and deadens sound in HVAC applications. Available in a range of thicknesses from 0.0625 - 0.25-in (1.59 - 6.35-mm) not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal Glass Pad

A black, flexible, low to medium-density (7 - 15 lbs/ft3)(112 - 240 kg/m3) industrial grade PVC foam cast to a high-gloss paper to achieve a foam surface that adheres to non-porous substrates, yet is removable and can be re positioned. Available with adhesive so the foam can be laminated to cork or other substrates. Available in a range of thicknesses from 0.0625 - 0.25-in (1.59 - 6.35-mm) not recommended for continuous use at temperatures above 180°F (82°C).

Novagard® Foam Seal Topper-Seal

A black, flexible, low-density (5.5 - 9 lbs/ft3) (88- 144 kg/m3) light-duty industrial grade PVC foam tape cast on PET. Designed for use as a seal between pickup truck caps and body side rails, it's also effective in a variety of non-critical sealing applications. Available in a low density foam cast on PET. 3/16 or 1/4-in (4.8 or 6.4-mm) thickness, in black or gray. Not recommended for continuous use at temperatures above 180°F (82°C).

Pres-Bond™ VF1200 & VF1100 Series PVC Foam Tape

Pres-Bond VF1200 and VF1100 PVC foam tapes feature closed-cell medium-density PVC foam with a one-sided pressure-sensitive acrylic adhesive backing. Pres-Bond tapes are designed for gasketing and sealing and have excellent resistance to water and other fluids. Pres-Bond tapes also provide a long-life seal against light, dust, and air penetration, and because they can cushion and absorb shock, they are widely used in sound, electrical and thermal applications.

Standard rolls are 52 in x 75 ft (132 cm x 22.9 m) and 52 in x 45 ft (132 cm x 13.7 m) and are available in thicknesses from 0.125 to 0.25 in (3.2 mm to 6.4 mm).

Pres-Bond™ VF5000 Series Reverse-Wound PVC Foam Tape

Pres-On VF5000 Series Reverse Wound PVC Foam Tapes feature closed-cell PVC foam with a one-sided pressure-sensitive acrylic adhesive backing and are available in the following material densities: VF5600 Sof-Seal, VF5100 and VF5700 low density, VF5300 medium density, and VF5400 high density.

VF5000 Series Tapes are used within transportation, automotive, appliance, construction, HVAC, retail, and general assembly industries as lighting enclosure seals, door and air filter gaskets, inlet gaskets on RVs, roof curbs, and log home seals.

Standard rolls are 52 in x 75 ft (132 cm x 22.9 m) and 52 in x 45 ft (132 cm x 13.7 m) and are available in thicknesses from 0.125 to 0.75 in (3.2 mm to 19.1 mm). Custom widths are available.

PORON® Microcellular Polyurethanes

Rogers line of PORON® Industrial Polyurethanes provides durable, long-term performance in industrial applications. Whether in gasket design, sealing, cushioning, or vibration management, the PORON line of products is low-outgassing, non-fogging, non-corrosive, and will not become brittle and crumble. The wide range of PORON materials available meets versatile design requirements.

PORON® 4701-15: Improved Soft Seal

The lowest density offering in the PORON line of microcellular polyurethanes. Enhanced surface toughness, reliability, and durability for thinner design applications. Ideal for use as dust-blocking gaskets in electronics and acoustic dampening. Available thicknesses include 0.53, 0.75, and 1 mm (0.021, 0.030, and 0.039 in.) at a density of 104 kg/m3 (16 lb/ft3). This product is gray and supported on a 2-mil (0.05mm) polyester film (PET), creating a permanent bond.

PORON® 4701-30: Very Soft

A very soft and easily compressed polyurethane foam. Maintains its integrity and effectiveness in gap filling, gasketing, and vibration isolation applications and is ideal in applications where flexibility is a key requirement. This material is black, available in the thickness range of 0.031 to 0.5 in (0.79 to 12.7 mm), and in densities of 320 or 400 kg/m3 (20 or 25lb/ft3). Recommended application temperature range of -51 to 121° C (124° F to 250° F) with constant use at 90° C (194° F).

PORON® 4701-30: Very Soft (Supported)

This material has the same basic performance characteristics as unsupported PORON® 4701-30 but is supported by being directly cast onto a 2 mil polyester film. By casting directly onto the film, a permanent bond is created. Available in a thickness range of 0.021 to 0.095 in (0.53 to 2.36 mm) and in densities of 320 or 400 kg/m3 (20 or 25lb/ft3).Recommended application temperature range of -51 to 121° C (124° F to 250° F) with constant use at 90° C (194° F).

-

- 4701-30-25021-04 P - Density: 25 lbs/ft3, Thickness: 0.021 in

- 4701-30-25037-04 P - Density: 25 lbs/ft3, Thickness: 0.037 in

- 4701-30-25047-04 P - Density: 25 lbs/ft3, Thickness: 0.047 in

- 4701-30-20064-04 P - Density: 20 lbs/ft3, Thickness: 0.064 in

- 4701-30-20095-04 P - Density: 20 lbs/ft3, Thickness: 0.095 in

PORON® 4701-40: Soft

A soft and easily compressed black polyurethane foam that offers excellent dimensional stability, is extremely durable, and maintains integrity in lengthy temperature fluctuations. Ideal for applications in portable electronics, automotive, aerospace, and more. Available in a thickness range of 0.031 to 0.5 in (0.79 to 12.7 mm) and in densities of 240, 320, or 480 kg/m3 (15, 20, or 25lb/ft3).Typical compression force deflection of 41, 76, or 173 kPa (5, 11, or 25 psi). Recommended application temperature range of -51 to 121° C (124° F to 250° F) with constant use at 90° C (194° F).

PORON® 4701-50: Firm

A firm, extremely durable black polyurethane foam with excellent compression set resistance, providing shock and impact management. This durable material can maintain its integrity and effectiveness, even when exposed to long periods of fluctuating temperatures. An ideal choice for energy management and gasket applications. Available in a thickness range of 0.012 to 0.5 in (0.30 to 12.7 mm) and in densities of 240, 320, or 480 kg/m3 (15, 20, or 25lb/ft3).Typical compression force deflection of 69, 117, or 269 kPa (10, 17, or 39 psi). Recommended application temperature range of -51 to 121° C (124° F to 250° F) with constant use at 90° C (194° F).

PORON® 4701-50: Firm (Supported)

This material has the same basic performance characteristics as unsupported PORON® 4701-50, but is supported by being directly cast onto a 2 mil polyester film. By casting directly onto the film, a permanent bond is created. This material has a thickness of 0.012 in (0.30 mm) and a density of 480 kg/m3 (25lb/ft3)

PORON® 4701-60: Very Firm

A very firm, extremely durable black polyurethane foam with excellent compression set resistance, providing shock and impact management. This durable material can maintain its integrity and effectiveness, even when exposed to long periods of fluctuating temperatures.

An ideal choice for energy management and gasket applications. Available in a thickness range of 0.031 to 0.25 in (0.79 to 6.35 mm) and in densities of 240, 320, or 400 kg/m3 (15, 20, or 25lb/ft3).Typical compression force deflection of 249, 428, and 643 kPa (36, 62, or 93 psi). Recommended application temperature range of -51 to 121° C (124° F to 250° F) with constant use at 90° C (194° F).

PORON® 4701-30-25047-04P Very Soft-Supported

PORON® 4701-30-25047-04 P Very Soft-Supported Polyurethane is commonly used for gasketing and vibration isolation applications at up to 250°F.

PORON® 4701-50: Firm (Thin as Cast)

PORON® 4701-50 Firm-Thin as Cast Polyurethane is commonly used for gasketing and energy management applications at up to 250°F.

PORON® 4790-92: Extra Soft - Slow Rebound

A black, extra-soft, slow rebound polyurethane foam with a very low closure force. Provides excellent protection for lower energy impacts. Conformable yet returns to its original shape, allowing for long-term performance. Great for gap filling and gasketing or sealing applications. Available in a thickness range of 0.125 to 0.5 in (0.79 to 3.18 mm) and in densities of 192 and 240 kg/m3 (12 and 25lb/ft3). Recommended application temperature range of -51 to 121° C (124° F to 250° F) with constant use at 90° C (194° F).

PORON® 4790-92: Extra Soft - Slow Rebound (Supported)

This material has the same basic performance characteristics as unsupported PORON® 4790-92 but is supported by being directly cast onto a 2 mil polyester film. By casting directly onto the film, a permanent bond is created. Available in a thickness range of 0.012 to 0.120 in (0.305 to 3.05 mm) and in a range of densities of 144 or 480 kg/m3 (9 to 30lb/ft3). Recommended application temperature range of -51 to 121° C (124° F to 250° F) with constant use at 90° C (194° F).

-

- 4790-92-30012-04 P - Density: 30 lbs/ft3, Thickness: 0.012 in

- 4790-92-25021-04 P - Density: 25 lbs/ft3, Thickness: 0.021 in

- 4790-92-25024-04 P - Density: 25 lbs/ft3, Thickness: 0.024 in

- 4790-92-25031-04 P - Density: 25 lbs/ft3, Thickness: 0.031 in

- 4790-92-25041-04 P - Density: 25 lbs/ft3, Thickness: 0.041 in

- 4790-92-20081-04 P - Density: 20 lbs/ft3, Thickness: 0.081 in

- 4790-92-15039-04 P - Density: 15 lbs/ft3, Thickness: 0.039 in

- 4790-92-15120-04 P - Density: 15 lbs/ft3, Thickness: 0.120 in

- 4790-92-12020-04 P - Density: 12 lbs/ft3, Thickness: 0.020 in

- 4790-92-12030-04 P - Density: 12 lbs/ft3, Thickness: 0.030 in

- 4790-92-12039-04 P - Density: 12 lbs/ft3, Thickness: 0.039 in

- 4790-92-12049-04 P - Density: 12 lbs/ft3, Thickness: 0.049 in

- 4790-92-12059-04 P - Density: 12 lbs/ft3, Thickness: 0.059 in

- 4790-92-09020-04 P - Density: 9 lbs/ft3, Thickness: 0.020 in

- 4790-92-09030-04 P - Density: 9 lbs/ft3, Thickness: 0.030 in

- 4790-92-09039-04 P - Density: 9 lbs/ft3, Thickness: 0.039 in

PORON® EVExtend® Battery Pad Material

PORON EVExtend battery pad material is the latest advancement in protecting and extending battery life. Designed to address the unique challenges of Electric and Hybrid-Electric Vehicle batteries, PORON EVExtend outperforms other battery pad solutions on the market, offering superior levels of reliability and long-term durability.

- Features

- Thickness range of .039 to .118 in (1 to 3 mm)

- Flat CFD Curve

- Tight specification of 5% on compression set (per ASTM D3574 at 70⁰C)

PORON EVExtend is available in two different variants:

BISCO® Silicones

Rogers BISCO product lines are the world’s leaders in silicone foams for gasketing and sealing applications. BISCO offers a wide range of cellular, solid, and specialty materials produced in roll stock. These high-performance materials are ready to be fabricated into gaskets, heat shields, fire stops, seals, cushions, and insulation.

BISCO® BF-1000 Extra Soft Silicone Foam

BISCO BF-1000 Extra Soft Cellular Silicone is a highly flame-resistant material, ideal for sealing outdoor enclosures, protecting electronics from shock and heat, and providing cushioning and vibration isolation. BF-1000 silicone's excellent memory and low-stress relaxation reduce maintenance costs from gasket failures caused by compression set and softening.

BISCO® BF-2000 Ultra Soft Silicone Foam

BISCO BF-2000 Ultra Soft is a highly compressible silicone foam with the right combination of low weight and softness for applications requiring low closure force and dust sealing. BF-2000 silicone's ultra-low softness allows designers to use less force to seal enclosures while protecting devices from the environment. This material is ideal for vibration isolation in electronic components and vehicles.

BISCO® RS-800 Series Flame-Resistant Silicone Sponge

The BISCO RS-800 series is trusted in various applications for gasketing and gap filling, including electrical enclosures, lighting fixtures, and transportation.

BISCO RS-800 products exhibit excellent flame resistance to UL94 when tested at a 3rd party lab, a compression set of below 10%, and high tensile strength and elongation. These properties make BISCO RS-Series materials resilient, enabling them to outperform competitive materials in challenging environments where superior silicone performance is needed.

BISCO® HT-820 Firm Silicone Foam

BISCO HT-820 Firm Cellular Silicone is a firm-grade silicone foam that provides enhanced durability and sealing. HT-820 foam offers a higher tear and tensile strength than BISCO lighter-grade foams. This material is designed for enclosures requiring a more durable, high-closure force gasket. HT-820 foam is ideal for sealing and protecting outdoor communication, lighting, and electronic enclosures from small dust particles, wind-driven rain, and fire.

BISCO® HT-840 Extra Firm Silicone Foam

BISCO HT-840 Extra Firm Cellular Silicone is a firm-grade silicone foam with superior sealing capabilities. HT-840 silicone provides a higher tear and tensile strength than Rogers' BISCO lighter-grade foams. HT-840 silicone is designed for enclosures requiring a more durable, high-closure force gasket. This material is also ideal for press pads requiring greater conformability and even pressure distribution at high temperatures. HT-840 silicone is a great choice for sealing and protecting outdoor communication, lighting, and electronic enclosures from small dust particles, wind-driven rain, and fire.

BISCO® HT-870 Soft Silicone Foam

BISCO HT-870 Soft Cellular Silicone is ideal for sealing outdoor enclosures, protecting electronics from shock and heat, and providing cushioning and vibration isolation. With excellent memory and low-stress relaxation, HT-870 silicone reduces maintenance costs from gasket failures caused by compression set and softening. Its extra softness allows designers to use less force to seal enclosures while protecting devices from the environment.

Closed Cell Neoprene Blend Foams

These Neoprene blend foams are suitable for most indoor and outdoor gasketing applications requiring a temperature range of -40°F to 150°F (-40°C to 65.6°C). They offer good alkali and acid resistance and stand up well to oxidation and the most common industrial fluids. Passes FMVSS-302 and is made with non-staining oils and anti-oxidants.

Meets ASTM D 1056-07 2A1/2C1 and SAE J-18 APR2002 2A1/2C1.

SSCE41NEO: soft-density material (7 - 11 lbs/ft3 / 112 - 176 kg/m3)

SCE42NEO: medium density (7 - 11 lbs/ft3 / 112 - 176 kg/m3)

SCE43NEO: firm density (12 - 20 lbs/ft3 / 192.2 - 320.3 kg/m3)

JBC Technologies can supply the SCE4-NEO foams in custom slit rolls ranging from 1/4" to 42" wide with or without adhesive backing or die-cut to shape.

Closed-Cell Neoprene/EPDM/SBR Blend Foams

Closed-Cell Neoprene/EPDM/SBR blend foams are a blend of Neoprene, EPDM (Ethylene Propylene Diene Monomer), and SBR (Styrene Butadiene) rubber. These materials show good resistance to ozone, sunlight, and oxidation, meet the requirements of UL157, UL50, UL508, and UL94HF-1, and perform well in applications exposed to operating temperatures in the range of -40°F to +200°F (-40°C to 93.3°C).

SCE41B: soft density (4 - 8 lbs/ft3 / 64 - 128 kg/m3)

SCE42B: medium-soft density (4 - 8 lbs/ft3 / 64 - 128 kg/m3)

SCE43B: firm density (7 - 11 lbs/ft3 / 112 - 176 kg/m3)

SCE45B: extra-firm density (11 - 15 lbs/ft3 / 176 - 240 kg/m3)

Closed-Cell EVA (Ethylene Vinyl Acetate) Foams

Closed-cell Ethylene Vinyl Acetate (EVA) foam is an odorless, lightweight foam rubber good for various industrial and commercial gasket and sealing applications. EVA foam is available in thicknesses from 0.0625" to 3" (1.6mm to 76.2mm) and exhibits excellent chemical resistance, good mechanical strength, buoyancy, low water absorption, and acoustic properties.

Meets ASTM D 1056-78, RE41, RE42/RE43 requirements, and FMVSS-302 flammability specifications.

Available in two varieties (black/gray/natural colors):

2# sheets 60in x 84in (1.5m x 2.1m) - 2# EVA

4# sheets 48in by 72in (1.2m x 1.8m) - 4# EVA

Closed-Cell Nitrile (NBR - Nitrile Butadiene) Foams

Closed-cell NBR (Buna-N) foam rubber is suitable for indoor and outdoor gasketing applications that require a service temperature of -40°F to 250°F (-40°C to 121°C). Closed cell Nitrile sponge offers excellent oil and UV resistance. Passes the flammability specification of FMVSS-302 and meets the physical property requirements of ASTM D 1056-67 SBE41.

C41NBR soft density

C42NBR medium density

C43NBR firm density

Can be supplied in rolls from 0.25" to 48" (6.35mm to 1.2m) wide with or without pressure-sensitive adhesive backing. We can also die-cut or waterjet cut to your specifications.

SEKISUI Volara® Closed-Cell Irradiation Cross-Linked Polyolefin Foam

Volara is a closed-celled, irradiation cross-linked polyolefin foam, available in roll and sheet form. It offers aesthetic appeal as well as an outstanding range of performance characteristics. Its smooth surface, consistent density, and uniform gauge offer superior physical properties.

Volara foams are resistant to most chemicals, and their low water absorption and vapor transmission rate make them a versatile, dependable foam solution. Volara polyolefin foams reach virtually all markets, such as transportation, general industrial, industrial tape, recreation & leisure, and tape & medical. Volara is available is several grades, including A, AS, AF, M, and many more.

SEKISUI Volara® Type A XLPE Foam

SEKISUI Volara® Type A is a low-density (2 - 6 lbs/ft3)(32 - 96 kg/m3) general-purpose crosslinked LDPE (XLPE) foam ideally suited for applications like flooring underlayment, construction gap filling, gasketing, and custom packaging. SEKISUI Volara® Type A is available in a thickness range of 0.063 to 0.420-in (1.6 to 10.7-mm) with standard colors of black and white (other colors available by custom order). Not recommended for continuous use in temperatures above 215°F (102°C)

SEKISUI Volara® Type AF XLPE Foam

Volara Type AF is an irradiation crosslinked polyethylene foam with a continuous smooth surface, fine cell structure, and excellent mechanical properties. Volara Type AF was developed to meet certain federal, military, and industry requirements on the flammability of cellular plastics.

Norseal® F-Series Foams

Norseal F-Series Silicone Foams provide impressive flame resistance, low compression set, and great conformability, making them a versatile option across multiple industries, including aerospace, EV/BESS, medical, and electronics. Norseal foams are typically used as thermal barriers, noise and vibration dampeners, thermal and electrical insulation, as well as gasketing and sealing. With its weather, moisture, ozone, UV, and fungus resistance, F-Series foams are a great material for harsh outdoor environments.

Norseal F-Series foams are available in multiple variants:

For more information Contact a JBC representative

While these downloadable material data sheets can get you started, they are just a portion of what JBC works with to meet our customers' needs. JBC converts a vast range of high performance gasketing, sealing, and shielding materials. With thousands of materials in stock, we offer fast turnaround while maintaining competitive pricing.