White Papers

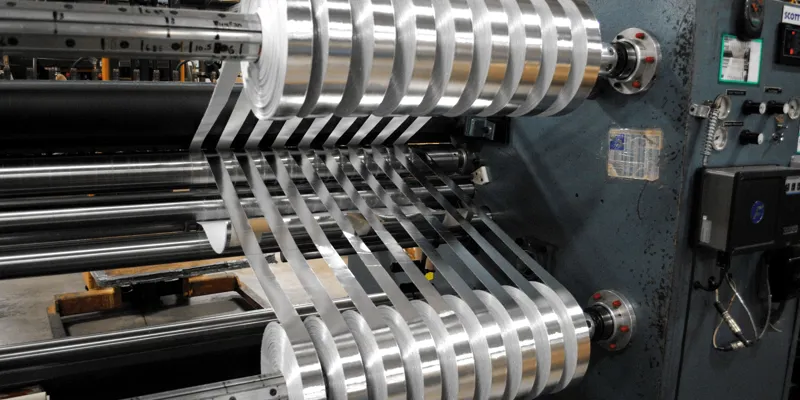

At JBC Technologies, we believe that the best decisions are informed decisions. The white papers below provide insight and information on some of the many materials we die-cut.

Click on a link below to download the document.

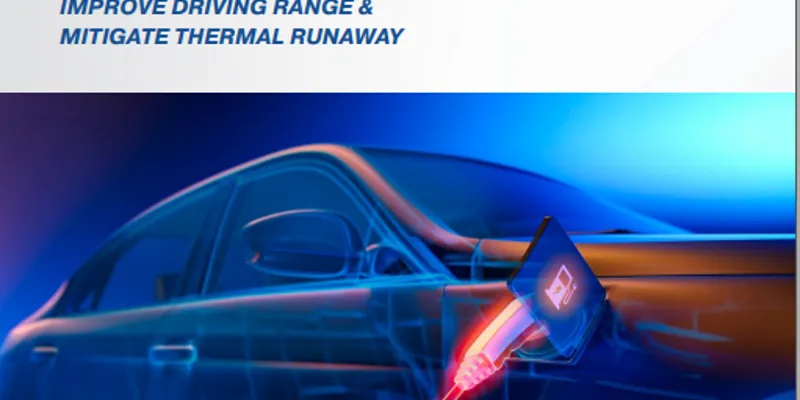

Passive Thermal Management Materials For EV Battery Applications

EV thermal management solutions are not always one-size-fits-all. Tackling thermal management properly requires customized, engineered materials solutions that have been tailored to each application's specific needs. In this white paper, we're covering everything you need to know about solving passive EV thermal runaway with flexible die-cut materials in and around the battery pack.

Whether you're looking to spread, insulate, or isolate heat, this helpful guide will get you started on the right track.

EV/ BESS The Impact of Die-Cut Tapes On Design and Scalability

Traditional mechanical fasteners and liquid adhesives can be bulky and difficult to produce at scale. For electric vehicle batteries and energy storage systems, where lightweight, scalability, and performance are everything, manufacturers are looking for alternatives.

This paper explores how pressure-sensitive adhesive (PSA) tapes can play a pivotal role in helping battery manufacturers address critical performance challenges, as well as the production efficiency-enhancing benefits that an engineering-driven flexible materials converter and die cutter can offer.

Thermal Management Solutions For Electronic Applications

To keep sensitive electronic components cool, design and application engineers are tasked with finding effective thermal management solutions that not only move excess heat away from critical components but do so within a smaller form factor.

This paper takes a closer look at how to approach the challenge using die-cut thermal management materials. Learn how consulting with a converting partner, like JBC Technologies, is key to developing the perfect thermal insulation solution for your project.

Quiet is Quality Die-Cut Solutions for Noise, Vibration, and Harshness

JBC Technologies works with many materials that solve critical challenges for noise, vibration, and harshness (NVH). Customers engage us at multiple phases in product development from early in the design stage to late in the game, when the product is ready to launch and a buzz, squeak or rattle has been discovered.

This article touches on the science of sound, provides high level insight into performance material options, and hits on five ways the right converter can positively impact your outcomes.

How to Avoid Getting Stuck When Selecting Skin Contact Adhesives for Long-Term Wear

The most important thing to know when selecting a skin contact adhesive for a long-term wearable medical device is that there is no one-size-fits-all solution. Strong yet gentle can be a tricky combination. A systems approach that examines all design and performance variables is necessary to ensure components work together to achieve the desired outcome.

This paper will highlight the key points to keep in mind throughout the product development process and serves as a guide to assist with adhesive selection.

Die-Cut Solutions to Stick to the Unstickable Bonding Low Surface Energy Materials

Getting things to stick and stay stuck has been a challenge for product designers and engineers for years. Compounding the problem is the proliferation of materials like thermoplastics and advanced composites because, thanks to a property called low surface energy (LSE), they’re notoriously difficult to stick to.

This paper discusses the relationship between surface energy and adhesion and introduces a few specialty tapes and adhesives designed to help turn LSE problems into sticky solutions.

Cutting to the Chase on Thermal Insulation Selection

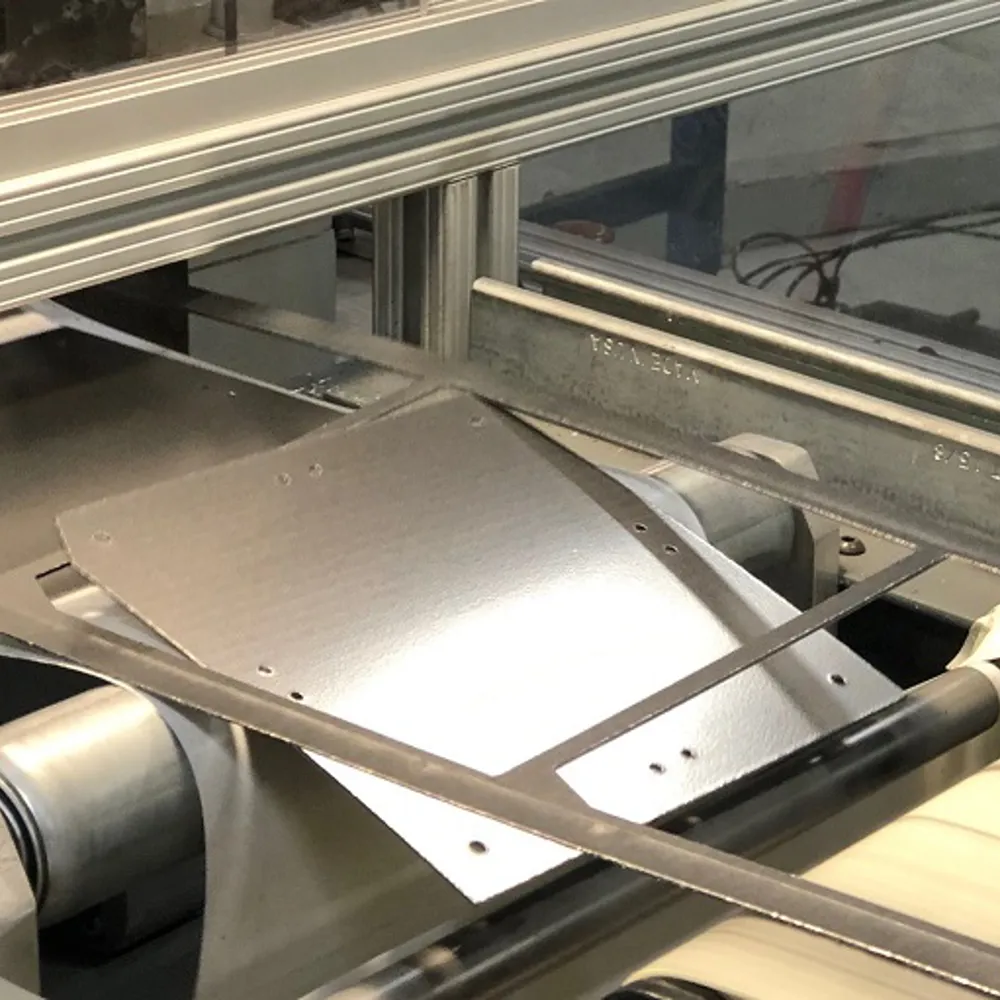

Because converters like JBC Technologies work directly with many different thermal insulation manufacturers to identify and source the raw materials we need to make die-cut and custom-engineered insulation panels and gaskets our customers, we have a unique perspective on challenges design engineers are trying to solve and the breadth of available solutions.

This paper highlights some key factors to consider when selecting thermal insulation material.

Solving Vehicle Hot Spots With Lightweight Alternative Heat Shields

With the Corporate Average Fuel Economy (CAFE) standards requiring improved fuel efficiency, lighter vehicles are a priority. This focus on automotive lightweighting means heavy heat shields don’t always measure up.

This white paper from JBC Technologies delves into the problem of hot spots and how to solve them.

UL Certification Demystified What You Need to Know About UL Certification and DieCut Components

Does UL certification matter for custom die-cut parts? The short answer is: it depends. UL certification of custom die-cut parts depends on many factors, including the application, the market, and regulatory requirements. In this whitepaper we'll look at UL certification, what it is, what it means for custom die-cut parts and the many benefits of obtaining UL certification.

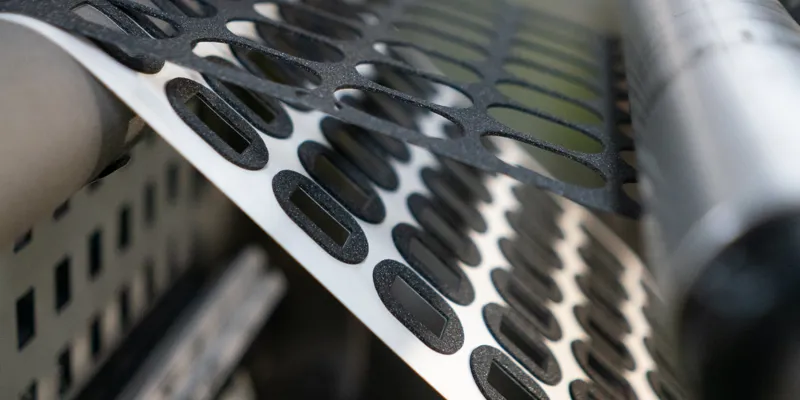

Die-Cut Solutions for Minimizing EMI/RFI in Connected Electronics

Nowadays, appliances do it all. They’ve become centerpieces for kitchens, function as entertainment centers and even connect to virtual assistants. Yet, the sensitive electronic components that power the interconnected and improved user experience of these devices are also increasingly susceptible to the challenges associated with Electromagnetic interference (EMI) and radio frequency interference (RFI).

The good news is that in many cases all of this can be addressed with a piece of custom die-cut specialty tape. This article addresses how.

The Anatomy of Medical Grade Pressure Sensitive Adhesives

Whether it's mouth tapes, breast lift tapes, diagnostic test strips, or attachment layers in patient monitoring devices, medical-grade pressure-sensitive adhesives (PSAs) are an integral part of the design of medical wearables. With so many PSA options available, choosing the wrong material or design for your final product can mean costly redesigns and production setbacks.

This white paper highlights the importance of understanding tape construction, performance requirements, and material options when designing a wearable medical device, to ensure you get your wearable device right the first time.

Need a Resource for Precision Die-Cutting? Contact JBC Today!

A 3M Preferred Converter, JBC Technologies provides innovative die-cut solutions that help turn design concepts into reality. But our impact goes far beyond converting flexible materials into custom parts. Our customers benefit from our strong engineering focus and emphasis on providing value during the full product lifecycle.