It’s Time to CUP Your Die Cutting Materials

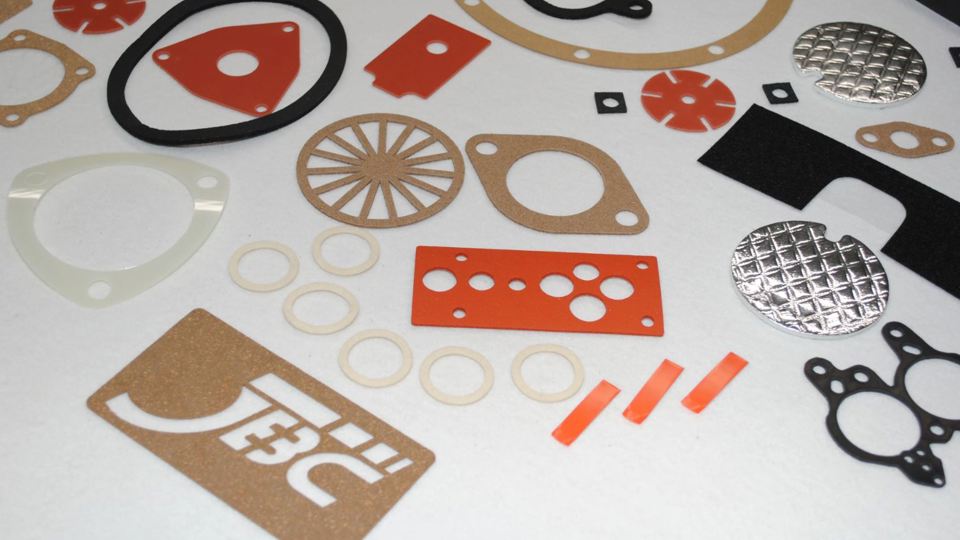

Engineers and sourcing managers need to ask tough questions to get the most value from their die cutting projects. In this blog entry, the first in a series called “Three Questions We Challenge You to Ask Your Current Die Cutter,” JBC Technologies examines the importance of material selection. If you’re not sure whether you’re using the right die cutting material, start with TAMP and continue to CUP.

In Material Selection Starts with TAMP, JBC explained the importance of TAMP, an acronym from 3M that describes the role of temperature, application, media, and pressure (TAMP) in material selection. Yet engineers also need to continue to CUP, an acronym from JBC that outlines three additional questions.

- What is the cheapest material (C) that will meet your application’s requirements?

- Am I using the most up-to-date (U) material available?

- What are the proper physical (P) characteristics to consider?

What is the Cheapest Material? (C)

If given the choice, most engineers would rather redesign a Ferrari than the family van. Sports cars are exciting, but they’re also expensive. So if your project’s budget is more like a mini-van than a Maserati, choosing an expensive Italian leather for the front seats isn’t the best option. Vinyl seats cost less – and they’re easier to clean and maintain, too. This same basic logic applies to die cut materials like PVC, aluminum foil, and EPDM. Unless you really need high-performance materials, don’t buy the Ferrari.

What’s the Most Up-To-Date Material? (U)

Are you using the same cell phone that you had three years ago? Probably not. Cell phone users replace their devices for a number of reasons, but typically it’s not just because something new came along (although that’s sometimes the case). Instead, owners replace their old products when they discover new ones that are better in terms of performance, cost, and reliability. Your old cell phone may have worked just fine, but you probably wouldn’t return the one you own now for the old “brick” you’ve replaced.

As an engineer, are you holding the die cut materials you specify to a different standard than your old cell phone? In other words, if you’re using the same rubber, plastic, or foil that you did three years ago, is it because these materials are superior to newer offerings? “Newer” isn’t the same as “better, and the fiery launch of the Samsung Galaxy 7 proves that point. But if you’re not using the most up-to-date die cut material today, you may be using the equivalent of a Blackberry when there’s a smartphone available.

What are the Proper Physical Characteristics to Consider? (P)

TAMP is widely-used acronym, but engineers may need to consider more than just temperature, application, media, and pressure. That’s why CUP is also about physical characteristics such as density and thickness. Specifying a material that’s too dense or too thick adds unnecessary costs and may affect performance. Choosing a material that’s too thin can also cause problems – including premature failure in the field.

Do you need assistance with material selection? Would you like to learn more about CUP for your next die cutting project? The Sales Team at JBC is ready to help. To get started, contact us.