Is Materials Science the Answer to the EV Battery Thermal Runaway Question?

As the electric vehicle (EV) industry continues to evolve, so does the technology behind the performance and safety of the batteries behind them. With increasing battery power and storage capacity come rising safety concerns, explicitly surrounding battery temperature management and thermal runaway.

Thermal runaway is the process whereby lithium-ion battery cells overheat and enter an uncontrollable, self-purpetuating chain reaction that can result in battery damage and even fire. A recent spate of EV battery fires and recalls at General Motors illustrates this point.

At JBC, we have experience converting performance materials, like those used in EV battery applications, into custom, die-cut solutions. But, before any converting is possible, the material manufacturers conduct a great deal of research and development work to ensure that their materials meet the exact demands of their intended applications.

Morgan Thermal Ceramics EST™ Compression Paper for EV Battery Applications: A Q&A

Today's post highlights Morgan Advanced Materials’ EST™ compression paper, a performance material developed to accommodate the cyclical expansion of pouch and prismatic electric vehicle battery cells. Jensen Plummer, R&D Engineer Automotive and LiB Development at Morgan Advanced Materials, shares his knowledge of EV battery thermal management and the role EST™ Compression Papers play.

Are you ready to learn more about how this engineered material can help improve electric vehicle battery performance and safety?

Q: Why is thermal management important in EV battery applications?

A: Quite simply, there is a lot of energy in EV batteries. As the market develops and consumer needs continue to evolve, you must keep pumping more energy into these systems. So, what do you do with that thermal energy when something goes wrong?

We like to highlight a few different studies. The numbers may vary slightly, but laptops typically have nine to twelve cells—the energy equivalent of a hand grenade.

When you scale this up to an EV battery, you're looking at the energy equivalent of about one-tenth of a tomahawk cruise missile.

It's a lot of energy to deal with. A key engineering challenge is to ensure occupants and surrounding objects are protected. Protecting adjacent modules or cells from that energy release is critical in an emergency.

Q: How do Morgan Advanced Materials EST™ compression papers help thermal management?

A: First, EST™ stands for Energy Storage Technology. These materials were developed specifically for lithium-ion battery thermal runaway management in automotive, stationary storage, or other applications. The compression papers are part of the EST™ family.

They are designed to mimic the cyclic compression of most polyurethane foams or some stiffer silicone foams, depending on the need (typically pouch and prismatic cells).

So why is that important? Cyclic compression and keeping force and pressure in the right amount on the battery from beginning to end of life conditions is critical to cell health.

The EST™ compression papers are ceramic fibre materials with minimal endothermic and organic material. The organic material allows it to meet compression requirements, while the ceramic fibre, endothermic, and off-gassing fillers assist if something goes wrong. So now you have a dual-use material with a thermal barrier, as well as that cyclic compression. The combination helps save on space and cost while increasing safety all at the same time.

Q: What are the key performance improvements provided by the EST™ Compression Paper?

A: It depends on the application. If a customer is looking at foam replacement, the key performance improvements are the usability temperature and very low thermal conductivity. Additionally, the material is lightweight. For higher-end automotive and aerospace applications, even a few grams difference in weight can make or break the success of an application.

If you're comparing it to a traditional insulating ceramic fiber paper, the critical performance improvement is that cyclic compression. Traditional ceramic fiber papers can't breathe with the cell on charge and discharge, which is crucial for cell health.

Of course, the goal is to keep the cell healthy for as long as possible. However, when or if it becomes unhealthy and goes into a thermal event, the EST™ Compression Papers are designed to mitigate the event.

Q: What makes EST™ Compression Paper better than the alternatives?

A: The key phrase is dual use. There are good thermal insulators and compression pads on the market; however, having high performance in both categories is unique to Morgan’s product portfolio.

This allows for the ability to tailor a compression curve (within reason) to what the customer need, whether for something that cycles repeatedly or needs a thermal barrier. It could also be soft and squishy for a pouch cell or more robust for a module or prismatic cell. These papers fill those needs.

Q - What are some typical applications for EST™ Compression Paper?

A - There are a variety of applications where these materials could be used; however, passive fire protection is the most common. EST™ Papers were explicitly developed for lithium-ion batteries but are suitable for any application that needs protection in case something goes wrong. The EST™ Compression Papers work if you want something that springs back or breathes with a system.

Metals expand and contract when they get hot. Therefore, these materials can maintain contact and pressure as an event happens, whether triggered by a lithium-ion battery or an external fire. A few examples include building and construction and marine applications.

Q: Can you tell us a little about the history of EST™ Compression Papers and how they've evolved?

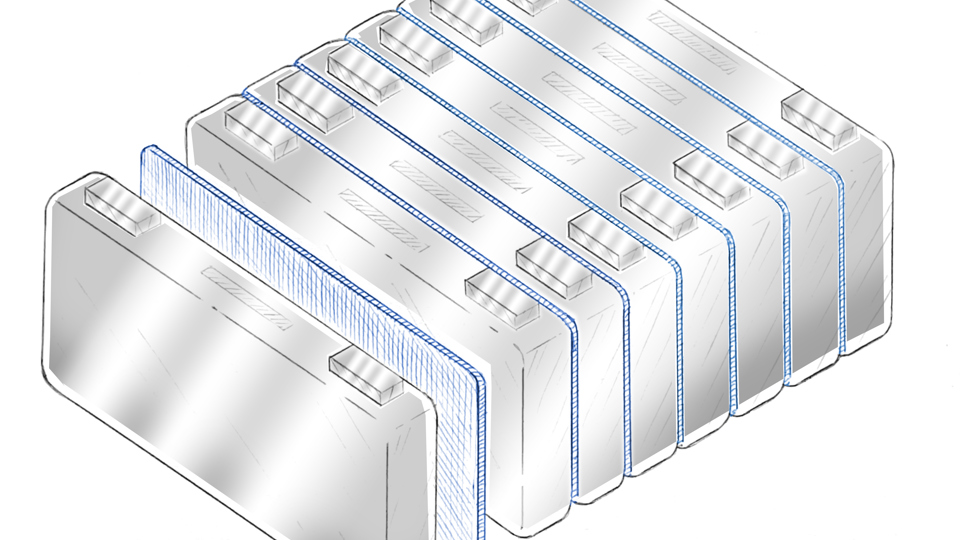

A: Morgan was founded in 1856 and has been in the high-temperature market from the very beginning. About ten years ago, we took our knowledge and understanding of high-temperature environments and passive fire protection and applied it to the battery space creating EST™ Block (shown right).

EST™ Block was the first material in our EST™ product portfolio, and from there, we developed the compression papers. In this emerging market there are many ideas on how to stop a thermal event, each with pros and cons.

Some go down the electrically conductive route, and some choose the immersion route. The majority of our products follow the isolation route. Morgan continues to develop this suite of materials to meet a variety of needs as the market progresses.

Q: Have the EST™ Compression Papers been tested to prove their effectiveness?

A: Although this is a relatively simple question, it can get quite complex because things are very design dependent. So just because one OEM successfully uses this material in their design doesn't mean it's the answer for everyone.

Morgan does different sets of compression testing to gain confidence in the materials, including compression set and cyclic compression with the customer's specific cells. Frequently this data is owned by the customer, and we provide the material for testing. We can also help with testing if we're going to share ownership of the data.

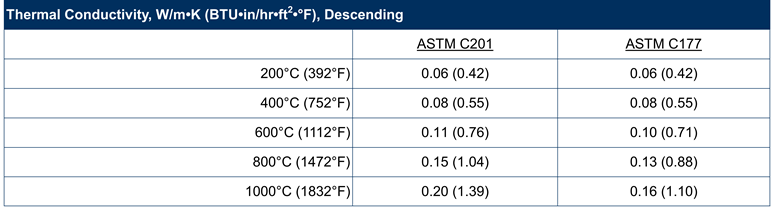

Morgan Advanced Materials EST Compression Paper, Thermal Conductivity Test Results

For the thermal events, we have sponsored live cell testing. However, typically we support our customers with their live cell testing. We love to be present in person or see a video of the testing to offer feedback as the testing process progresses.

Overall, a combination of screening techniques provides confidence for live cell testing. We have available direct flame impingement testing, hot air impingement testing, and hotplate testing. We always invite customers to come to watch the screening test as well. It depends on the application, which is why getting the engineering teams talking is so important.

Q: When it comes to electric vehicle battery testing, can you explain the differences between simulation and live cell testing?

A: First, it is expensive to do live cell testing. Second, it is dangerous to do live cell testing and screening tests with an open flame, shrapnel, etc. Instead, customers often rely on simulation. With RAs simulation technology advances, I think it will be possible to simulate and capture the complete picture.

However, until then, it is a bit challenging to use simulation effectively. Therefore, we always encourage customers to continue progressing with the material into live cell testing and comparing it to the simulation.

Q: Why should the end-use customer, material converter, and material supplier connect early in the development process?

A: What's interesting is that we see a shift in the market. The discussions we've been having in the last two years mean customers are coming to us early in the development process to ask questions about improving the safety of their application, meeting global standards, or collaborating on space concerns.

It has been a more collaborative interaction in the last couple of years, which fits well with the way we like to work with our customers.

Q: Do EST™ Compression Papers use sustainable/green materials?

A: As part of our strategic sourcing process, outlined in our Conflict Minerals Policy, we include due diligence risk assessment of our suppliers. Morgan also makes a lot of the raw materials that go into these products, and that vertical integration helps contribute to our green initiatives by reducing carbon emissions from transportation.

We use alkaline earth silica (AES), a low biopersistent ceramic fiber, to eliminate any possible health and safety concerns from carcinogens found in other ceramic fibers. We also recycle the majority of the water used in the manufacturing of these products to avoid being a burden on local systems.

We aspire to use water sustainably across our business. Our 2030 target is to reduce our overall water usage by 30% and our water usage in high-stress areas by 30% (from a 2015 baseline).

Q: What are a few highlights of the Morgan Advanced Materials EST™ Compression Papers?

A: We offer two versions of compression paper: the C30 and the C310. The C stands for compression, and the number indicates the pressure in KPA that it takes to get to 20% compression, which is a typical beginning of life requirement.

These papers feature our low biopersistent Superwool® fibres and are designed for a pouch or prismatic cells to mitigate thermal runaway propagation. Both products meet UL94 V-0 requirements, provide an excellent finished surface, are easily cut to shape, and feature an adhesive-capable design. For more information, check out the product datasheet.

Q: How do you and Morgan Advanced Materials help customers find the right products for their applications?

A: It all starts with getting the technical groups together. The customer tells us what's essential for their application so we can make the best recommendation from our product portfolio. Typically, this involves going over the compression forced deflection (CFD) curve. We ask questions like:

- What type of cells are you using?

- What's the goal of this material?

- What do you have in the application today, or do you have anything?

- What is the available space for the material?

After discussions with the customer and the engineering team, we sample small quantities, usually from 10 to 100, depending on the part size. Then, we allow the customers to do their independent testing. We also ask if they want to see some of our independent tests.

Q: How does JBC Technologies - a material converter and precision die-cutter - add value to the EST™ Compression Papers?

A: One of the more frustrating properties of ceramic fiber is that it is dusty. Ceramic fiber manufacturing inherently incorporates shot (grains of glass not turned into fiber) and is not good to have in the packs.

Lamination, pressure-sensitive adhesives, full encapsulations, die-cutting, and other solutions a converter like JBC offers allow us to help our customers get finished parts ready for assembly.

Morgan Advanced Materials - EST™ Compression Paper Material Data Sheets

JBC + Morgan Advanced Materials = Value-Added Solutions

For over thirty years, JBC Technologies has utilized our engineering expertise and breadth of vertically integrated converting capabilities to turn rolls of flexible materials into custom die-cut parts.

As a premier flexible materials converter, JBC Technologies partners with industry-leading material manufacturers like Morgan Advanced Materials to provide our customers with the highest quality die-cut products.

Contact us today to learn more about how our custom solutions can help you convert your design concepts into reality.

Additional Reading from Morgan Advanced Materials

No ‘One Size Fits All’ Approach to Thermal Runaway in Electric Vehicle Batteries