6 Thermal Management Materials for EV Battery Applications

Electric vehicles are poised to play a big part in the global push towards a more environmentally conscious future. General Motors announced a plan to discontinue the production of Internal Combustion Engine vehicles by 2035 and Mercedes Benz, by 2025. Other automakers have announced similar timelines. Now the race is on to build a better mousetrap – more specifically a lighter weight, faster-charging, longer-lasting high performance EV battery. This requires the effort of many talented engineers and organizations at all levels of the EV supply chain, including the manufacturers of specialty materials and companies like JBC Technologies that convert those flexible materials into functional parts that play critical roles in the safety and performance of the EV battery.

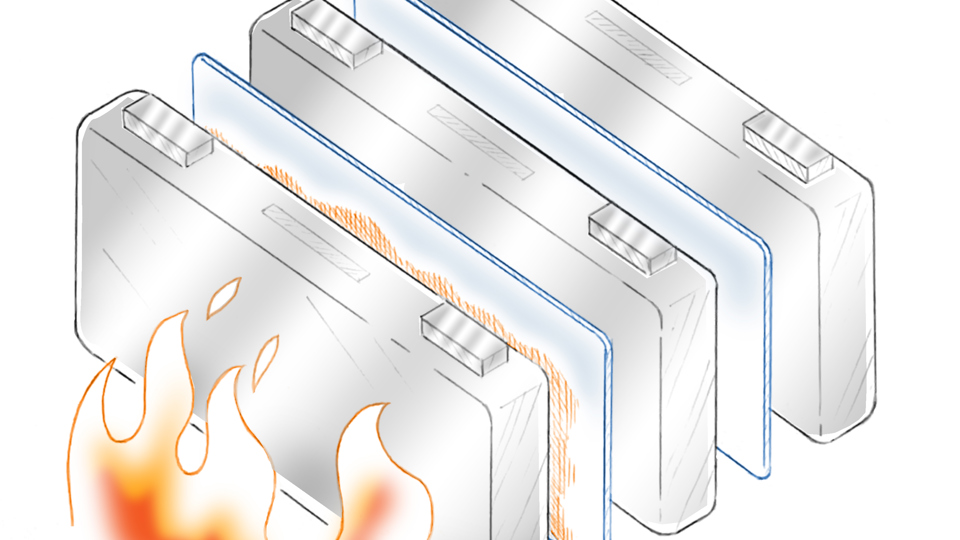

Li-ion batteries perform best when maintained within an optimal temperature range. Temperatures less than 5°C or more than 50°C can lead to significant battery degradation and thermal runaway.(source) The challenge is exacerbated by the consumer’s desire for a rapid charge and discharge, both of which add to heat management issues. Too hot or too cold and thermal instability can occur leading to thermal runaway that can at best destroy the cell and at worst start a vehicle fire.

Reducing this thermal instability is where many of the performance materials that we convert at JBC Technologies come into play. Die-cut performance materials such as the ones described below can be used at the cell level, the module level, and even the pack level. Example applications include cell isolation, battery isolation and battery housing insulation.

This post highlights just a few of the Thermal Management materials we can convert at JBC.

Ceramic Papers – Morgan Advanced Materials

With classification temperatures from 1100 to 1300℃ and strong compression resistance, EST™ (Energy Storage Technology) Compression Papers from Morgan Advanced Materials are designed to prevent or delay the propagation of thermal runaway. They can not only accommodate the cyclical expansion that pouch, and prismatic cells experience during normal operation, but they can also be used to solve challenges with thermal energy absorption and thermal resistance. They meet UL-94 V-0 requirements, can be converted by an experienced die-cutter, and are NOT classified as carcinogenic by IARC or under any national regulations on a global basis.

Compression Resistance Performance Properties - kPa (psi)

EST C30

- 20% deflection 25 - 35 (3.6 - 5.0)

- 60% deflection 380 - 470 (55 - 68)

- UL94 Rating > or = 1mm UL94V-1 All other thicknesses

EST 310

- 20% deflection 295 - 340 (43 - 49)

- 60% deflection 1700 - 1970 (247 - 286)

- UL94 Rating UL94 V-O All thicknesses UL94V-0

Morgan has a variety of EST products to meet a variety of different design challenges.

Ceramic Papers with Mica Laminate - Morgan Advanced Materials

UL94V-0 rated, EST Paper M, also developed by Morgan Advanced Materials, was specifically made for use in module-to-module protection scenarios. It is a mica laminated paper designed to offer strong performance in high temperature environments. The mica facing allows for higher dielectric strength values and enables the spread of the heat on the hot face in the x and y directions. The insulating Superwool® Paper is intended to prevent the heat from spreading in the z direction to the cold face.

Thermal Performance Properties @ 600°C (1112°F), 20 minutes

- 1mm (0.04) thickness <230°C (<446°F)

- 3mm (0.12) thickness <200°C (<392°F)

- 6mm (0.24) thickness <140°C (<284°F)

Flexible Graphite - NeoGraf

Neograf’s eGraf® SpreaderShield™ - which has been widely adopted in the marine battery space for nearly a decade - is steadily gaining traction as a material of choice within the EV space. Due to its strong heat spreading ability, flexible graphite can be used to maintain cell temperature uniformity during charge and discharge cycles. It can be encapsulated in PET (Mylar), die-cut, and used as a stand-alone product. It can also be highly effective when laminated to a material such as Rogers PORON® or EST™ (Energy Storage Technology) Compression Papers and used as an integral layer of a multi-functional material stack.

Key Characteristics

- Anisotropic ratio up to 300:1

- Thicknesses as low as 17μm

- 30% lighter than Aluminum and 80% lighter than Copper

- Spreads heat up to 4x of Copper and 7x of Aluminum

Aerogels - Aspen Aerogel

Aspen Aerogels offers a line of lightweight, ultrathin PyroThin™ thermal and fire barrier materials intended to enable efficient thermal management. Their featured EV products include:

- PYROTHIN™ ATB1000 – Available in 2 and 3mm thicknesses, PyroThin™ ATB1000 is designed for use in space-constrained applications.

- PYROTHIN™ ATB2000 – Also available in 2 and 3mm thicknesses, ATB2000 has been optimized to deliver increased mechanical performance.

Learn more at https://www.aerogel.com/industries/battery-thermal-barriers/.

Polyamide Papers - Nomex

Another group of performance materials that is being positioned for EV Battery applications is the family of Nomex polyamide papers, from Dupont. The Nomex® 410 family of insulation papers offers high inherent dielectric strength, mechanical toughness, flexibility and resilience. Additional benefits include

- 220˚C continuous usage

- Flame retardant to UL94 V0

- Low thermal shrinkage – <0.1% at 300˚C

- Available in 11 thicknesses ranging from 0.05 mm to 0.76 mm (2 mil to 30 mil)

Options specifically developed for the EV Market include Nomex® CellShield™ ; Nomex® SafePak™

Adhesives - Avery Dennison Performance Tapes

While a tape or adhesive alone cannot truly be classified as a thermal management material ¾ and will not by itself stop a thermal runaway event within the battery pack ¾ it can play an important part in the success of the overall material stackup that does. As such it is something to be considered.

Avery Dennison Performance Tapes offers a variety of materials for bonding the abovementioned performance materials to each other as well as to cells, modules, and pack structures. These include single- and double-coated filmic tapes for fiber encapsulation and dielectric strength as well as flame-retardant adhesives that enable composites and materials to meet UL® 94 V-0 and other flame requirements.

For a more detailed look at how die-cut adhesives play a part in Thermal Management for EV Batteries read our Q & A with Scott Krusinski, Product Manager - Automotive & Other Transportation at Avery Dennison Performance Tapes North America.

Thermal Runaway Tape Product Portfolio

Convert Your Electric Vehicle Concepts to Reality with Die-Cut Thermal Management Solutions from JBC Technologies

As a cutting-edge flexible materials converter, JBC Technologies partners with many industry leading material manufacturers to provide our customers with the highest quality die-cut products. Whether your goals are lightweighting, improved EV battery range, thermal management, bonding, sealing, or gasketing, we can help. Contact us today to learn more about how our custom engineered die-cut solutions can help you achieve your goals.