Pulse Oximetry Adhesive Selection - Part 2

Pros and cons of synthetic rubber, acrylic, and silicone-based adhesives in die-cut pulse oximetry applications

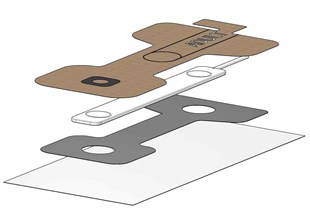

As we mentioned earlier in 9 key factors to consider when selecting an adhesive tape for your pulse oximetry application there are multiple layers that go into a disposable die cut pulse oximetry bandage, and each of those layers will have varying performance requirements.

| But the device layer isn’t the only thing that will drive adhesive selection – use case is also important, specifically when it comes to the skin contact layer. For example, some tapes are designed to be worn over the course of several days, while others are designed for relatively short periods of time. Some require the need for removability / repositionability, others do not. Some are designed to be worn on neonates, others on very elderly patients. You get the idea. The variables are rather extensive. Fortunately, adhesives come in multiple formulations. |  |

Here’s a quick primer on the pros and cons of each.

Latex Free Synthetic Rubber Adhesives — For Applications Where a More Aggressive Bond is Needed.

While not the first thing that may come to mind for stick-to-skin medical devices, latex free synthetic rubber adhesives can be ideal for the skin contact layer of pulse oximetry applications that require 24/7 monitoring. Not only do they reach the desired adhesion level quickly, but they also provide reliable adhesion for securing the device to the patient’s body, ensuring accurate readings of oxygen saturation levels and pulse rate throughout the duration of use.

In the case of woven fabric, synthetic rubber adhesives are beneficial when the adhesive coated fabric must be applied to a finger or a toe and wrapped around onto itself. In this case a heavier coat weight of adhesive is helpful to adhere to the porous fabric as well as forming a strong bond when wrapped around onto itself

Lastly, they tend to be less expensive than their acrylic and silicone counterparts.

The downside of using synthetic rubber adhesives in skin contact applications can be that they do not have the same degree of repositionability as their acrylic and silicone counterparts. This issue can be combatted, however, using additives. DermaMed Coatings and others offer customizable synthetic rubber adhesives which can be optimized to minimize the initial tack, enabling repositionability and gentle removal from the skin at the end of the required wear time.

As a final note: Rubber adhesives have a higher tack ( a.k.a. stickiness) and lower shear (internal adhesive strength) than the acrylic options mentioned below. This makes them less suited for holding “heavy” sensors.

View product recommendations here

Acrylic Adhesives – For Applications Where a Higher Shear Strength is Desired.

Like synthetic rubber adhesives, acrylic adhesives offer strong adhesion to the skin for multiple days at a time. There are several key differences, however.

The first is the length of time it takes to achieve bond strength. The synthetic rubber adhesive will achieve its full bond strength much faster, whereas an acrylic adhesive will increase in adhesion over time.

The second is the internal adhesive strength (shear). Due to their higher internal strength, PSA tapes with high shear are less likely to split under stress and therefore more suitable for holding “heavy” sensors.

Lastly, acrylic adhesives can be more suitable than rubber adhesives if skin-sensitivity or high- temperature resistance is a concern.

Check out these top tapes for pulse oximetry applications.

Silicone Adhesives – For Short-Term Wear Applications Where Repositionability is Key

Silicone adhesives are considered the best for short-term wear-sensitive skin applications requiring low trauma upon removal.

On the plus side, a silicone adhesive can be applied to the body several times and still maintain the same bond strength, which is ideal when there is a need for multiple readings in a short period of time.

On the downside, it would not be ideal in a pulse oximetry application where the patient was moving a lot (as might be the case with an infant). It also comes with a higher price tag than its rubber and acrylic counterparts.

Related Reading - Pulse Oximetry Tape Converting

- Top Skin-Contact Adhesive Tapes for Pulse Oximetry Applications

- Adhesive Selection for Disposable Pulse Ox Applications - Part 1

- 6 Reasons to Work with JBC Technologies for Your Pulse Oximeter Bandage Converting Needs

Contact JBC Technologies for Your Next Die Cut Pulse Oximetry Project

| With over a dozen state of the art Rotary Die Cutting presses, rapid prototyping, inline printing capability, multiple clean rooms, and strategic partnerships with some of the best medical tape manufacturers in the industry, JBC Technologies is your go to supplier for Die Cut Pulse Oximetry Tapes. To schedule a consultation to discuss your custom medical die-cutting project, contact us today. |