Adhesive Selection for Disposable Pulse Ox Applications - Part 1

As we have discussed in previous blog posts, there are many applications for die cut skin contact adhesives. Today’s focus is on disposable pulse oximetry tape applications.

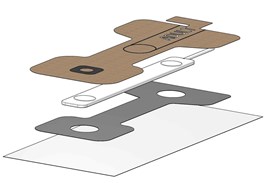

The Anatomy of a Die Cut Pulse Oximetry Tape

Pulse oximetry bandages are typically made up of multiple layers of die cut tapes and adhesives, all with different functional requirements and physical makeup.

| While not every disposable pulse oximetry device is the same, there are several common factors. There is a typically a printed face layer (the part the patient will see), adhered to a sensing device, which is adhered to a light blocking layer with a skin contact adhesive, which is then adhered to a delivery release liner (think of the roll that is left behind after you peel off a sticker). |  |

The adhesive tape that is used for the printed face layer does not need to pass skin contact requirements but should still pass biocompatibility testing.

The adhesive that affixes the device to the skin needs to meet both skin contact and biocompatibility criteria. It is used to create a tissue‐sensor optical coupling—and ideally maintains that coupling during movement so it must be firm enough to hold the device on the skin, yet still gentle, as there is the potential for adhesive-related Medical Adhesive Related Skin Injuries (MARSI) with any skin contact adhesive application.

> Read about the pros and cons to each of the major adhesive types.

A Pulse Ox Adhesive Selection Checklist

We have touched on several of these key points already, but to summarize, there are several things that need to be taken into consideration when selecting adhesive tapes for the various layers of your disposable pulse oximetry device:

- Skin compatibility – For the skin contact layer specifically: Does the adhesive pass biocompatibility testing? Will it minimize the risk of skin irritation and discomfort during extended monitoring periods?

- Adhesive strength – Is the adhesive strong enough to support the weight of the device and maintain adhesion throughout the patient monitoring cycle? Will it be strong enough to ensure accurate readings of oxygen saturation levels and pulse rate?

- Flexibility & conformability – Does the tape construction lend itself to uncompromised adhesion to curved body parts such as fingers and toes?

- Ease of removal – for skin–contact layers, can you remove the bandage without inflicting the patient with a medical adhesive related skin injury (MARSI)? For those not familiar with MARSI issues, this video from 3M is a helpful resource.

- Breathability – Is the tape breathable enough to prevent moisture build up and skin maceration with prolonged use?

- Moisture resistance – Will adhesion be maintained when the tape is exposed to sweat and other body fluids?

- Interaction with the sensor – Will the tape construction enhance or detract from the sensor performance? Light blocking properties are important to prevent the ambient light from the hospital setting negatively impacting the accuracy of the readings/ sensor.

- Printability – does the tape support a clear, readable print?

- Repositionability – while this is not necessary in all use cases, if the application requires it, you will want to make sure that the adhesive you choose enables removal/ reapplication without loss of adhesion

> View product recommendations for adhesive tapes for pulse oximetry applications.

Remember: No single pressure sensitive adhesive tape exists that performs as needed across all applications. Therefore, when selecting adhesives for a pulse oximetry application it is important to use a multi-step evaluation process to narrow down the available options to arrive at the best product for your application.

And it is also a good idea to consult your flexible materials converter early in the process. Partnering with an experienced medical die cutter like JBC Technologies that has strategic partnerships with medical adhesive tape manufacturers early in the design build process will streamline development and production.

"Pulse oximeter sensors consist of many material layers including pressure sensitive adhesive tapes which are used for assembly and for attachment to the patient. One of the critical layers in the sensor is a metalized adhesive coated film. This metalized film is used as a reflective layer to help enhance the efficiency of light reflection within the sensor assembly. By reflecting light back to the photodiode, accuracy and sensitivity of the sensor that is measuring oxygen saturation levels are improved. The metalized film also serves the purpose of light-blocking within the sensor preventing ambient light from entering the sensor which could interfere with the accuracy of the sensor readings." - Aaron Smith, DermaMed Coatings

Work With an Experienced Pulse Ox Converter

|

We hear repeatedly that one of the biggest mistakes made when selecting adhesives for wearable medical devices is waiting till the end of the design process to bring converting and adhesive partners into the discussion. Failing to consider all the variables that direct adhesive selection and manufacturing process early can lead to costly product delays and redesigns. JBC can assist throughout the full product lifecycle, from with material selection and prototyping to full contract manufacturing. Our team has over a century of combined expertise in material selection, product design, and process engineering. |

|

With an ISO 8 / Class 100,000 cleanroom, inline printing, and state-of-the-art die cutting and other converting equipment, JBC Technologies provides high quality solutions for the medical industry – from pulse oximetry bandages, and wound dressings to custom fashion and cosmetic tapes.