Bonding Low Surface Energy (LSE) Materials

Engineered materials like thermoplastics (e.g. Nylon, COC, COP and PEBA, TPO or TPE) and composites are increasingly being used in place of metals for automotive, appliance, aerospace, electronics, and medical applications. Yet while there are significant benefits to these materials, they are very difficult to adhere to due to a phenomenon called surface energy.

Historically, manufacturers who wanted to use adhesives for bonding instead of mechanical fasteners got around this problem by using primers or surface treating. Both of these methods, however, require extra time and processing steps and in the case of primers, the obstacles are compounded by the fact that many primers pose environmental hazards.

This article, the first of a three-part series, will explain the importance of surface energy in the bonding process, and how 3M low surface energy (LSE) adhesives allow for a clean and secure bond on low surface energy plastics. We’ll also outline four high-level steps to ensure that you choose the best tape for your project.

Why Surface Energy Matters

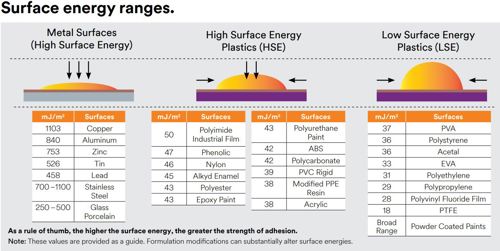

Surface energy is the amount of excess energy residing on a given surface. Surface energy dictates how easily a surface will “wet out,” or allow for a liquid to spread out. On materials with high surface energy, like metal, the liquid will easily spread out and cover the surface and form a secure bond. On materials with low surface energy, like many plastics, the liquid will bead up and resist flowing. This makes low surface energy plastics tough to stick to.

To illustrate this point, imagine the hood of a car. When it rains, water will naturally flow off the hood. This is because the hood is made of metal and has high surface energy which allows the water to spread out and flow. Now, imagine that the hood of the car has been waxed. Since wax has lower surface energy than metal, the water will bead up and resist flowing.

Adhesives Formulated to Bond Low Surface Energy Plastics

3M™ offers a variety of tapes and adhesives that are specially formulated to bond low surface energy materials without the need for surface preparations like plasma treating or primers. They can be divided into two main categories: transfer tapes and double-sided tapes – with acrylic foam tapes as a subset of the double-sided category.

Transfer Tapes

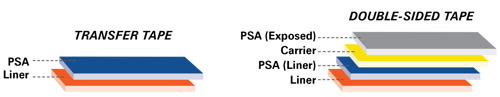

Transfer tapes consist of an adhesive layer on a release liner usually made from film or paper. Since the adhesive sits directly on each surface, transfer tapes are ideal for thin, low profile bonds as well as more conformable solutions. They are commonly used for electronics components and membrane switches.

Two examples of LSE transfer tapes are 3M™ Adhesive Transfer Tape 9472FL and 3M™ Adhesive Transfer Tape 9453FL, both of which are ideal for high-speed rotary die-cutting.

See more low surface energy adhesive data sheets here.

Double-Sided Tapes

Double-sided tapes utilize a “carrier" - a thin layer of foam or film - with an adhesive coating on each side. A liner will appear on one or both sides of the tape. Double-sided tapes offer increased durability, vibration dampening and have a variety of uses including permanent and temporary bonding, sealing, and spacing.

Two LSE examples transfer tape examples that support precision die-cutting include: 3M™ High Strength Double Coated Tape 93015LE and 3M™ Double Coated Tape 9495LE.

See more low surface energy adhesive data sheets here.

Acrylic Foam Tapes

Among 3M’s double-sided tapes is VHB™, a proprietary acrylic foam tape featuring a foam carrier with increased viscoelasticity. The adhesive bond builds strength over time, while the foam carrier absorbs energy, relaxes stress, and accommodates shear, tensile, and compression loading.

For years, 3M's VHB has been an ideal solution for bonding a wide variety of materials. But it wasn't until quite recently that VHB joined the LSE game. Recognizing that more and more manufacturers could benefit from a low surface energy version of the product, 3M™ introduced their VHB™ Tape LSE Series to the U.S. market at the beginning of 2020. Not only does it effectively adhere to LSE thermoplastics such as polypropylene, TPO, and TPE, but it can also stick to a number of other innovative new materials that exhibit low surface energy without the need for primers and adhesion promoters.

See VHB™ Tape LSE Series data sheets here.

Choosing the Right Adhesive – The Fundamentals

The surface energy of the substrate is just one of many factors that go into choosing the right adhesive for your die-cut parts. The technical specialists at JBC Technologies have years of experience in this area and are here to help should you need it. We also have the benefit of the collective knowledge of our industry-leading suppliers. We recommend reaching out to our team early on during the design stage of your products, as we may be able to save you time and effort later on down the line. Should you decide to pursue adhesive selection on your own, here are a few high-level pointers with links to learn more.

- Understand the Attributes of the Substrates You Are Bonding - Substrates differ in terms of material, texture, the presence of contaminants, levels of surface energy, and more, all of this can impact what type of adhesive will work best for your application. Read more about substrates and adhesion here.

- Know the Environmental Conditions the Adhesive Will Need to Withstand Long-Term - Environmental factors that should be considered include exposure to excessive heat or cold, moisture, solvents, oils and greases, and more.

- Evaluate Stress at the Bond Line – Understanding the long-term stresses that will be placed on the bond line will help you identify the necessary peel adhesion, tack, and shear of the adhesive. Read more about stress and adhesive bond strength here.

- Consider How the Adhesive Will Be Used – The pressure-sensitive adhesives that we convert at JBC can be grouped into three basic types: permanent, removable, and repositionable. Each has its own unique purpose and it is important to select the right type for your application.

For more information, read this guide to preventing adhesive failure.

Increase Efficiencies with Custom Die-Cut Solutions

By now, you’ve determined the surface energy of the desired bonding product, considered all key attributes for the product design, and know where to find datasheets for the LSE solutions in 3M’s versatile lineup. You’re almost there.

Now, it’s time to pull in the converting experts at JBC Technologies. A 3M Preferred Converter, JBC converts many different types of materials, from foams, films, and felts to nonwovens, SMS materials, and even foils. And… you guessed it, adhesives.

We work with manufacturers across a wide range of industries, helping our clients across all stages of the manufacturing process—from assisting with material selection and prototypes to full-volume production. Our value analysis/value engineering approach means that we’re always looking for new ways to improve our clients’ experience.

What we’ve found is that sometimes, the smallest change can make a massive difference. As part of our mission to add value wherever possible, JBC examines all aspects of the manufacturing process, from packaging to presentation to delivery systems.

Here are just a few examples of some of the things that JBC can do with LSE Adhesives to get them ready for prime time in your production environment:

- Laminate to a foam, felt, film, non-woven, or other material of your choice

- Die-cut to a custom shape

- Slit to custom widths

- Kiss cut to a liner – with the addition of a pull tab for ease of assembly

- Adhere to (your) customer supplied plastic injected parts

- Index on a roll for automation

We’ve learned that adding value comes in many different packages: Sometimes it’s as simple as adding a pull tab to a product or eliminating corrugated packaging for orders. Other times, it is providing full VMI services. No matter what, JBC is committed to helping clients achieve their full potential.

If your next project requires a low surface energy adhesive, JBC Technologies and our partners at 3M are here to help. Contact us today, to get started.