Converting and Die Cutting Frequently Asked Questions (FAQ)

As a custom material converter and die-cutter, JBC Technologies is known for our ability to transform flexible materials into custom solutions like seals, gaskets, insulation, and even heat shielding.

So it's not surprising that we field hundreds of weekly questions from customers and customers-to-be about the different converting, die cutting, and performance materials we use. We've gathered the most commonly-asked questions on our most popular subjects and put them together in one place.

Welcome to the JBC Technologies Converting & Die-Cutting Frequently Asked Questions landing page. Click on the subject card below to learn more.

TABshield™ Thermal & Acoustic Barrier

TABshield from JBC Technologies is a lightweight thermal and acoustic insulation product that is an alternative (and sometimes enhancement) to traditional metal heat shielding. It's easy to install, conformable to most shapes, and an ideal solution for various targeted noise and heat suppression applications. Find answers to frequently asked questions here.

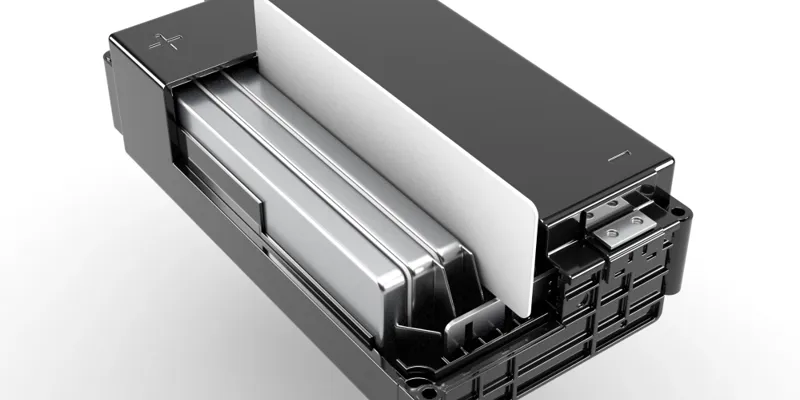

EST™ Compression Papers Battery Thermal Management

EST™ Compression Papers from Morgan Advanced Materials are designed to accommodate the cyclical expansion experienced by the pouch and prismatic battery cells during the routine operation of an electric vehicle. Learn more by reading this FAQ (and answer) page.

eGraf® Flexible Graphite Heat Spreading

Neograf Solutions eGraf® flexible graphite products mainly include thermal management solutions for heat spreading and thermal interface of electronic and battery applications. The Neograf flexible graphite products feature a variety of thermal properties, each delivering a broad range of performance attributes. Learn more by reading through this FAQ.

ITW Formex Electric & Thermal Barrier

Formex™ is a proprietary plastic (polypropylene) sheeting that combines dielectric strength with UL-94 flame resistance. Formex™ can resist moisture absorption, making it a good choice for outdoor applications, such as IP cameras and access control systems, and can be die-cut into custom shapes. Answer your questions here.

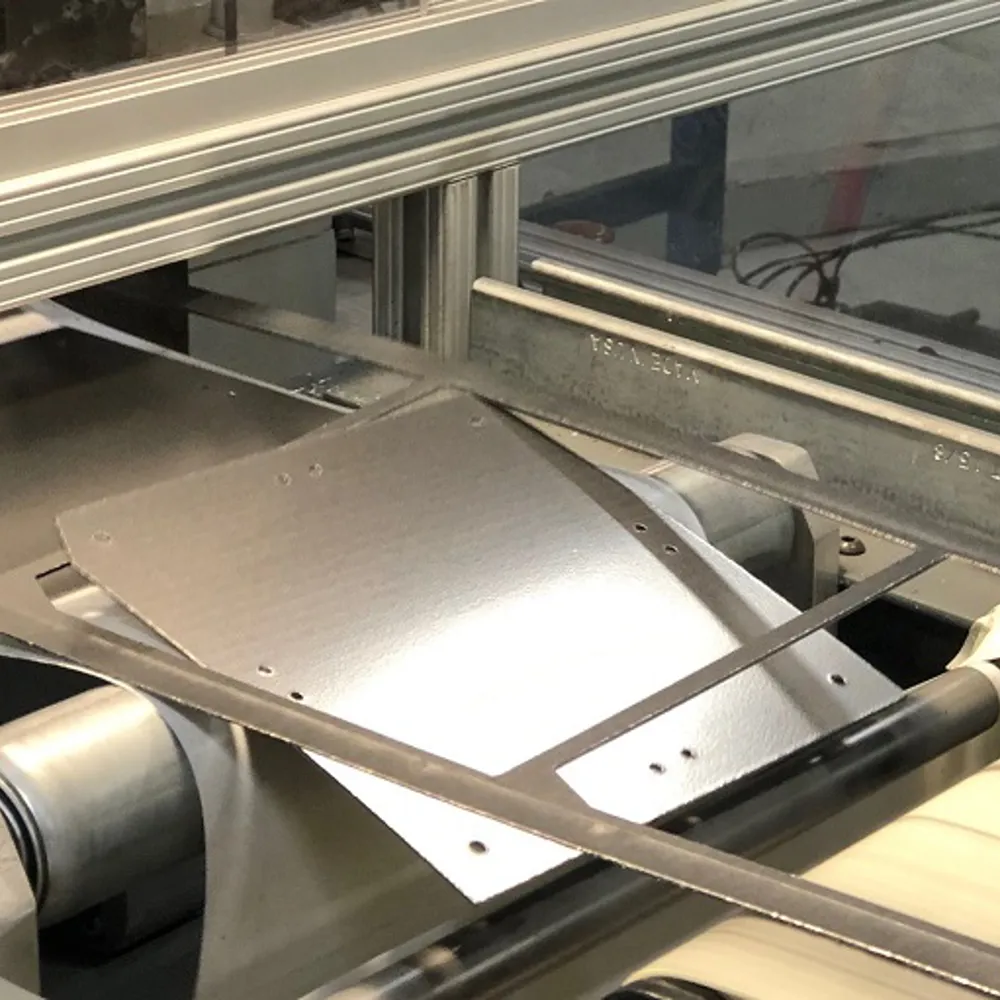

Rotary Die Cutting High Speed. Tight Tolerance.

Rotary Die Cutting is one of our primary manufacturing methods at JBC Technologies. Our stable of state-of-the art equipment enables us to make high volumes of complex multi-layered parts with extremely tight tolerances. Interested in learning more about what makes this specialized manufacturing technique an excellent fit for medical devices, automotive, and other industries? Check out our FAQs page.

UL Certification for Custom Die-Cut Parts

UL certification is an important factor to consider when selecting custom die-cut parts. It demonstrates a commitment to safety and compliance, increases customer trust and confidence, and can lead to increased sales and business opportunities. Obtaining UL certification for custom die-cut parts can be a complex process, but at JBC Technologies, we are dedicated to assisting our customers in the UL certification process.