Electric Vehicle and Energy Storage System Gasketing and Sealing Solutions

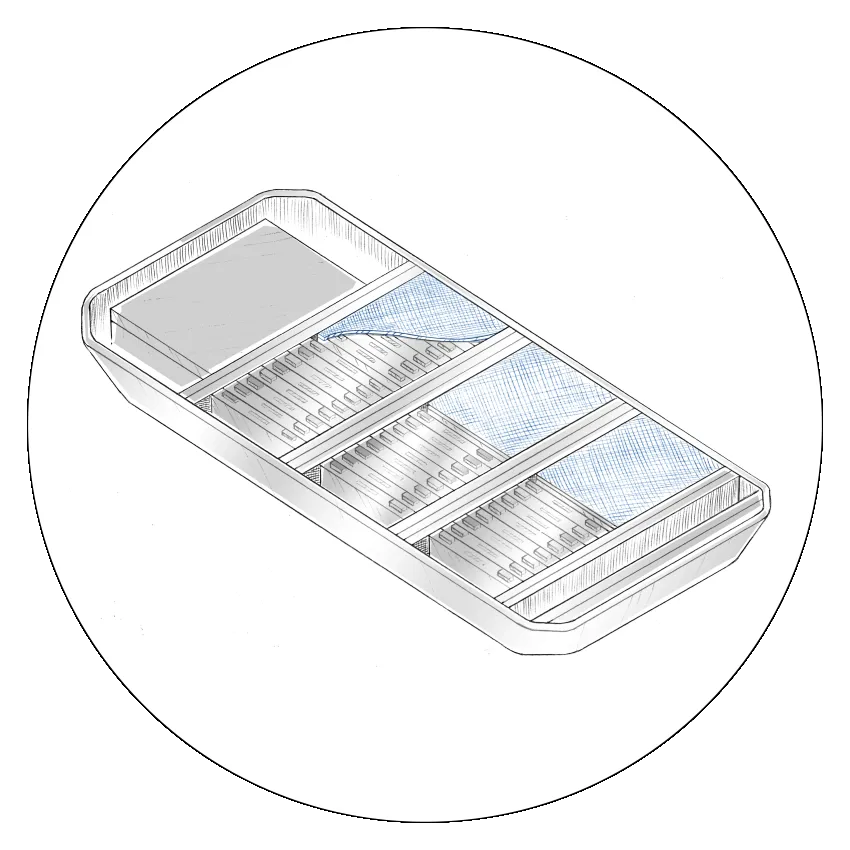

A key factor in a battery system's performance and durability is keeping the battery pack sealed off from the environment. Custom die-cut seals and gaskets from JBC technologies provide a comprehensive spectrum of battery pack, module, and cell alternatives.

APPLICATIONS

Seals and gaskets in electric vehicle and energy storage system batteries are used to protect the battery from environmental factors like dust, moisture, and heat. They also help to maintain the integrity of the battery by preventing electrolyte and other fluids from leaking outside of the battery pack in the event of a rupture.

- Battery pack (upper and lower sections)

- Maintenance entry points

- Cooling plate and liquid delivery system

- Venting caps

- Module sealing

- Battery cells

- Terminal isolation

Battery gaskets and seals are effective options for preventing environmental contaminant ingress and imparting thermal insulation for heat-sensitive components. They also provide fire protection and shielding against electromagnetic interference (EMI).

Custom die-cut seals and gaskets made for the EV/ESS marketS can be made of various grades of rubber, or elastomers, each with THEIR own specific performance properties and advantages, like flame retardancy and chemical resistance.

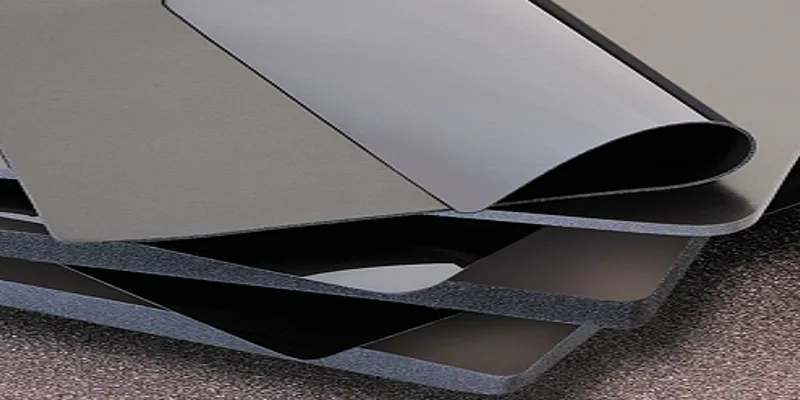

pERFORMANCE MATERIALS

Performance materials include silicone foam rubbers to butyl-coated PVC and micro-cellular PUR foams. Low compression set foams and fire-blocking solutions protect the battery pack by sealing its components from the environment.

The experts at JBC Technologies can help you select the right materials for your EV/ESS battery gaskets and seals. Over the last 30 years, we’ve continued to build strong partnerships with the world’s best foam and gasket material manufacturers – 3M, Saint Gobain, Armacell, Nitto, Rogers Corporation, NovaGuard and more.

Choosing a suitable material for your battery gaskets and seals – a material that is both cost-effective and durable – is crucial for their long-term performance and durability. You want only the best materials, and we can help you get them.

Here are a few of the specialty materials you’ll have available for your custom die-cut Battery seals and gaskets.

Acrylic Foam Tapes

EV/ESS batteries require special adhesive tapes for their gaskets and seals. Adhesive tapes must often be tested against UL 94 for flammability performance or UL-Listed for safety regulations. Specialty adhesive tapes like 3M’s VHB and Avery Dennison AFB acrylic foam tapes offer both strong bonding and sealing in one material.

Silicone Foam

Silicone foam is designed to reduce weight as well as mitigate thermal runaway and provide protection from moisture, debris, vibration and shock for electronic components and battery packs. Die-cut components made from silicone foams, like those from Saint Gobain, are also ideal where flame protection, low smoke, and toxicity are necessary.

Gaskets manufactured of BISCO silicone material offer outstanding temperature and UV resistance in addition to sealing off water, dust, and debris.

Microcellular Polyurethane

With its ability to maintain a constant force, PORON polyurethane material keeps battery cells isolated, protected against liquids and dust, and insulated from the potentially harmful effects of vibration.

Your Partner. For Custom EV/ESS Battery Gaskets & Seals

When you choose to work with JBC Technologies for your custom battery seals and gaskets, you get a world-class converter and precision die cutting expert, along with the technical and product development support of the industry’s leading material manufacturers.

No project is too simple or too complicated. Whether you need a single material with a high-temperature adhesive backing or a multiple-layer, multi-material composite die-cut with tight-tolerance design aspects and presented on rolls for automated assembly, you can count on JBC Technologies.